Waste motor oil, transmission fluid, and other types of fuel are common byproducts of various industrial and household activities. Unfortunately, disposing of these materials can be both expensive and environmentally damaging.

However, what if you could salvage these fuels and turn them into something useful? With a little effort and the right tools, you can recycle these fuels and give them a new lease of life.

STEP 1 : FILTERING THE WASTE OIL

Filtering waste fuel is one of the common methods of recycling it. However, the cost of filter materials and the need for constant replacement can make this method expensive and time-consuming.

Fortunately, there is an alternative solution that is more efficient and cost-effective: using a centrifuge.

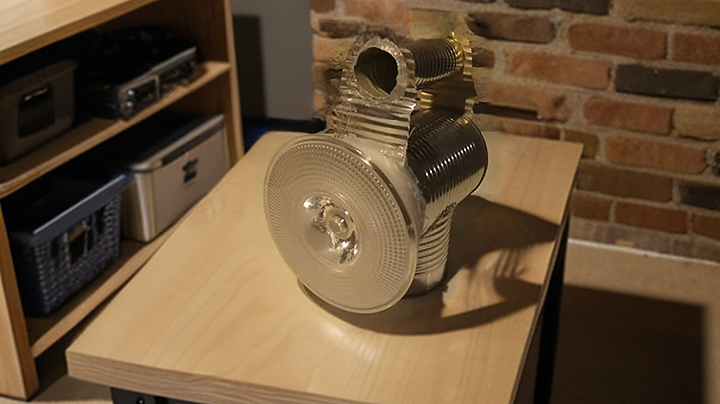

The centrifuge is a specialized machine that separates the different components of a liquid based on their density through high-speed rotation.

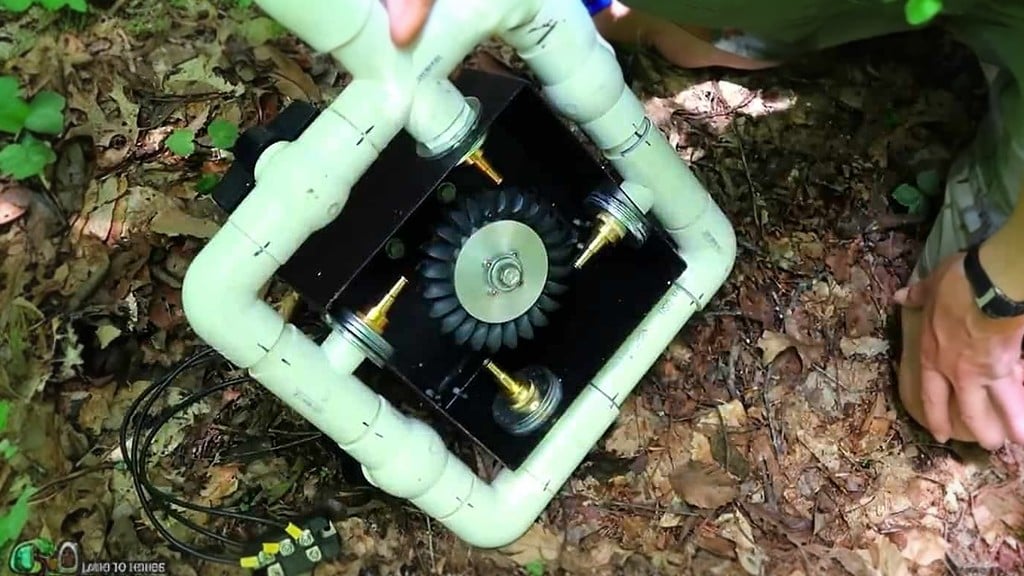

The USfilterMaxx centrifuge is one such machine that has been designed specifically for recycling waste fuel.

By pouring waste motor oil, transmission fluid, or old diesel into the top of the centrifuge and spinning it at high speeds, impurities are separated from the fuel, leaving behind clean, usable fuel.

In the initial test, waste motor oil is poured into the centrifuge and spun at a rate of 3000 RPM or higher.

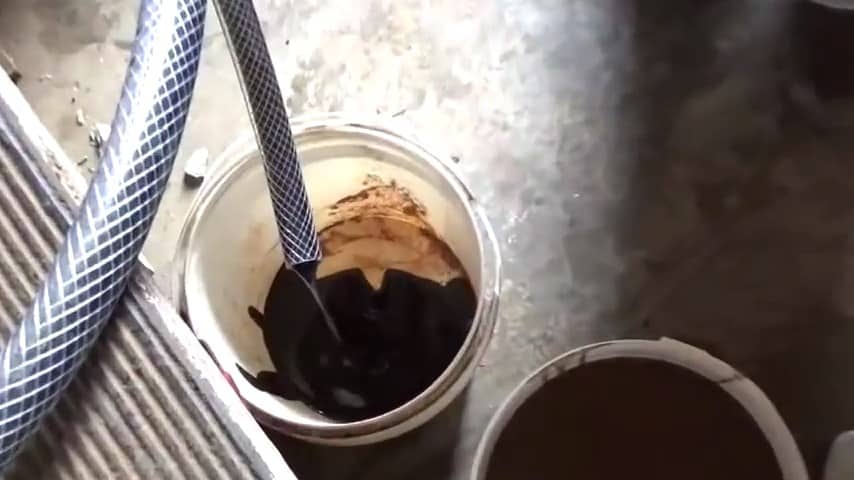

After the centrifuge has completed its cycle, the waste fuel is drained from the machine. The result is two separate materials: sludge and clean motor oil.

The sludge is the waste material that was filtered out by the centrifuge, while the clean motor oil is now ready to be used as a fuel source.

It’s important to note that when using this method with diesel engines, caution must be exercised. Improperly mixing fuels can lead to damage to the engine’s injectors, resulting in costly repairs.

However, for older diesel engines that are more forgiving, this recycling method can be a great solution for providing sustainable fuel options.

STEP 2 : RUNNING THE CENTRIFUGE

Once the waste oil has been poured into the centrifuge, it’s time to start the machine and begin the filtering process. As the centrifuge spins, the waste oil is introduced and begins to separate into its different components.

During this process, it’s important to monitor the amount of filtered oil that is being produced. In this particular test, a batch of two-and-a-half gallons of waste oil is being filtered.

Once the desired amount of filtered oil has been produced, the centrifuge can be shut off.

However, it’s important to note that the true measure of the success of the filtration process cannot be determined until the centrifuge has completely stopped spinning.

This is because all of the sludge and impurities that were filtered out during the process are stuck to the outside wall of the machine.

Once the centrifuge has come to a complete stop, the sludge and impurities can be removed from the outside wall of the machine.

At this point, the remaining filtered oil can be drained from the centrifuge using the drain plug located at the center of the machine.

As the centrifuge spins at high speeds, it takes the waste oil that is poured into it and pushes it out towards the edge of the machine.

The force of the spinning causes the different components of the waste oil to separate based on their density.

At the outer edge of the centrifuge, there is a dam that separates the clean, filtered oil from the sludge and impurities that have been removed from the waste oil.

The clean oil is pushed over the dam and into a separate section of the centrifuge where it can be collected and used as a fuel source.

The centrifuge used in this process requires a 220 power source to operate.

Therefore, if you want to use a centrifuge to recycle your waste fuel, you will need access to either a generator, grid power, or a battery bank and inverter capable of supplying the necessary power.

Once the waste oil has been filtered through the centrifuge and the clean, filtered oil has been collected, it can be mixed with diesel fuel to create a sustainable fuel source.

In this particular case, a gallon and a half of the clean, filtered motor oil will be mixed with a gallon and a half of diesel fuel.

To accomplish this, a five-gallon jug is used to hold the mixture. The clean, filtered motor oil is first poured into the jug, followed by the diesel fuel.

The two liquids are then mixed together, resulting in a 50-50 combination of motor oil and diesel fuel.

STEP 3 : ADDING A HEAT EXCHANGER

To further improve the efficiency of the centrifuge, several modifications have been made to enhance the heating process and ensure that the oil is filtered to the highest possible standard.

One of the key modifications that have been made is the addition of a shell and tube heat exchanger made of copper.

This heat exchanger allows hot water to be used to heat the stored oil to a point where its viscosity is much lower, allowing it to spin out a lot cleaner.

This results in a higher quality of filtered oil that is ideal for use as a sustainable fuel source.

To power the heat exchanger, a solar direct drive water pump has been added, which is connected to a 20-watt solar panel.

This setup ensures that the centrifuge can operate off-the-grid, without the need for external power sources. The hot water is circulated through the shell and tube heat exchanger, ensuring that the oil is heated to the optimal temperature for filtering.

To prevent any vapor from escaping into the clean oil bucket, a P-trap has also been added. This ensures that any vapor from the hot oil is evacuated out of the sludge side, thereby preventing contamination of the clean oil.

Thermo siphoning using a used water heater is also used to provide easy heat for the system. This process requires no pumps, instead, it relies on the natural flow of heated water to provide energy.

The hot water is siphoned up to a tank and then a little solar pump is used to take the hot water off the top of that tank and run it to the shell and tube.

So pretty much off-the-grid water heating, heating lots of water using a thermal siphoning process.

Image Credits :Engineer775 |