In this project, we will be discussing how to build a simple and cost-effective wood gas generator that can be used to power a small 5HP electric generator.

The construction of this generator requires basic materials that can be easily sourced from around your home.

STEP 1 : THE SETUP

For the construction of this wood gas generator, we will be using a 20-gallon garbage can as the main generator. Inside the garbage can, we will be using a wine cooler as a component, and hanging a small steel bowl inside.

The wine cooler will be used to help cool the gas produced by the generator, while the steel bowl will serve as the combustion chamber for the wood gas.

The combination of these components will allow us to efficiently convert wood pellets into a usable gas that can be used to power our small electric generator.

STEP 2 : CONNECTING THE FILTER

After setting up the main generator, the next step is to connect it to the filter using a long aluminum duct line.

The filter, which will be used to purify the gas produced by the generator, has been filled with wood pellets.

These wood pellets not only help to filter out impurities from the gas, but they also serve as the fuel source for the generator.

As the wood pellets are heated, they produce a gas that can be used to power our small electric generator.

.

.

STEP 3 : AIR INTAKE

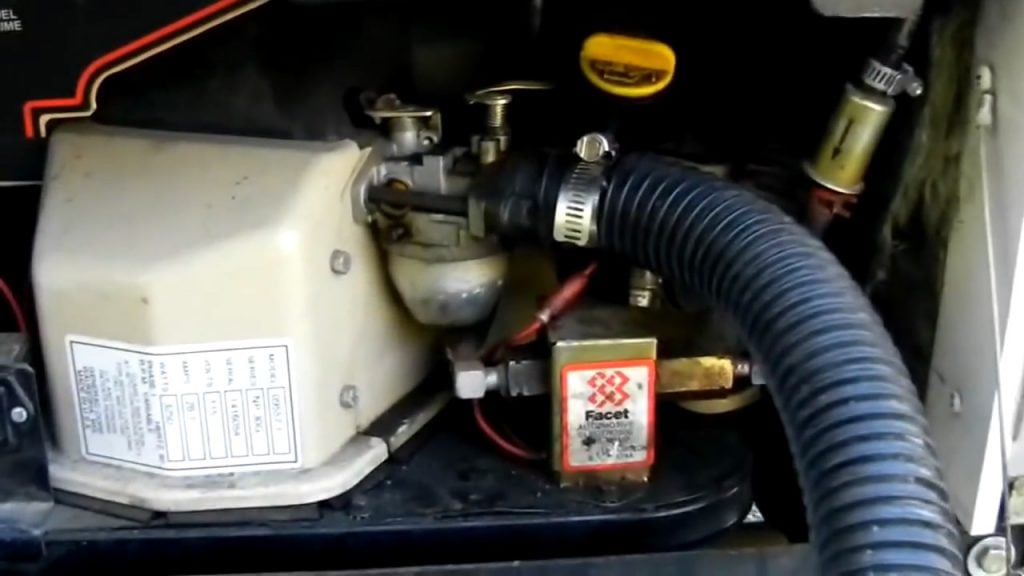

Once the wood gas has been filtered and purified, the outlet line is connected to an air inlet port to allow for the addition of air to the combustion process.

The valve used to control the flow of air is specially designed to optimize the combustion process and ensure efficient use of the wood gas.

The wood gas is then directed all the way to the RV gas engine to power it.

It goes all the way to the RV Gas engine.You can cut off the fuel by using a wire to cut off the fuel pump.

The 20-gallon garbage can is used as the filter, which requires a bit of modification. First, two quarter-inch holes are drilled into the can, and then they are enlarged using a nibbler.

A harbor wire is then placed into the can where the filter medium is dumped. Pine wood shavings are used as the filter medium, with approximately 1/3 of the can being filled up.

STEP 4 : THE REACTOR

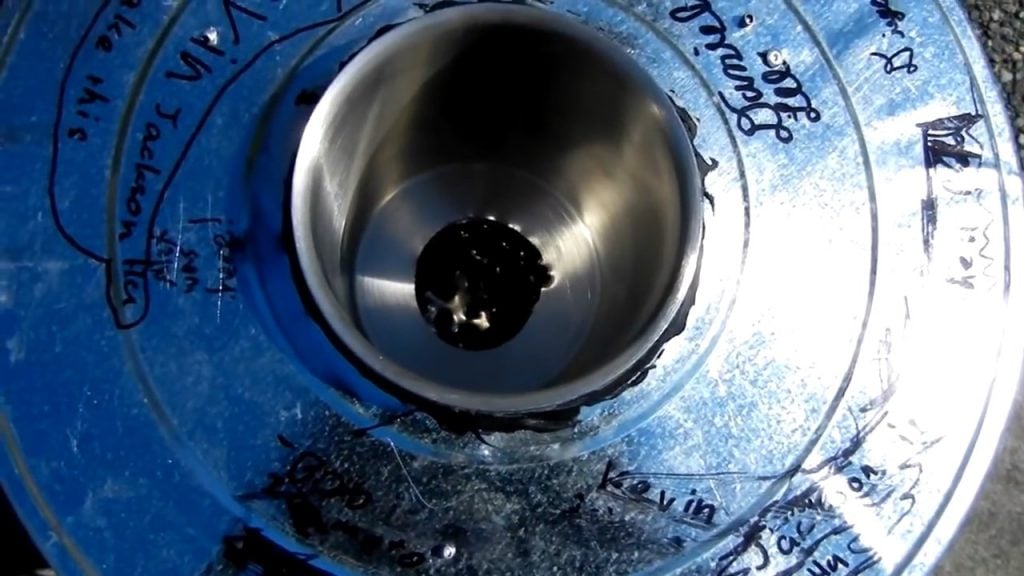

The reactor is constructed using a stainless steel thermos. The thermos is a central cylinder that is double-walled and has an opening of approximately one inch at the bottom.

This design allows for efficient gas production and easy access for cleaning and maintenance.

Below the thermos, a steel mixing bowl is hung by three chains that are riveted into the thermos. To optimize the combustion process, the mixing bowl is drilled with numerous holes to facilitate the even distribution of heat and air.

This design allows for the wood pellets to be efficiently converted into gas by ensuring that they are exposed to the proper amount of heat and air.

To connect the reactor to the main generator, a simple 20-foot dryer duct is used. The duct is made of lightweight aluminum and is easy to handle and install.

The dryer duct is a flexible and adaptable solution that can be easily modified to suit different needs and configurations.

After constructing the reactor, it is time to fill it with wood pellets to start producing wood gas. The wood pellets are added to the reactor, and the generator is started up.

As the wood pellets heat up and start to decompose, they produce wood gas, which is then directed to the main generator.

To cool the wood gas and improve its quality, a hose is stretched out from the reactor to the 20-gallon filter.

The filter serves as a cooling and purification chamber for the wood gas before it is directed to the generator.

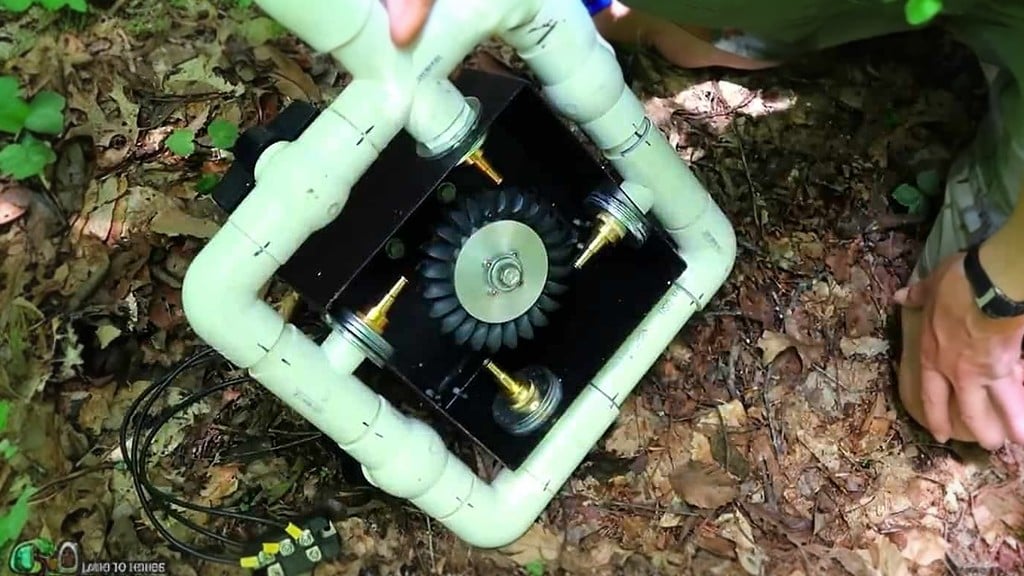

To power the wood gas generator, a small air mattress pump is used.The pump is connected to the generator, and once it is turned on, it begins to circulate air through the reactor and the 20-gallon filter.

To control the speed of the air mattress pump, a dimmer control has been rigged up. This allows for greater control over the combustion process and ensures that the wood pellets are being converted into wood gas at the optimal rate.

By adjusting the speed of the pump, it is possible to fine-tune the combustion process and improve the efficiency of the wood gas generator.