This article presents a comprehensive guide on the construction of a do-it-yourself Atmospheric Water Generator, capable of extracting and distilling water from the surrounding air.

The unit is composed of high-quality aluminum and copper components, ensuring its safety and the potability of the water produced.

With a distillation process comparable to traditional stove-top methods, this innovative system performs effectively in hot and humid conditions, while simultaneously acting as a dehumidifier. Its practicality is especially useful in areas with high humidity levels.

STEP 1 : MATERIALS REQUIRED

To construct your own Atmospheric Water Generator, you will require several materials that are easily accessible from your local hardware store or online retailer.

These materials include quarter-inch copper tubing, a soup can, half-inch PVC pipe, a 12V DC aquarium pump, aluminum foil, clear vinyl tubing, an aluminum tray to collect the distilled water, and a small styrofoam cooler box.

It is essential to ensure that the copper tubing and PVC pipe are of high quality and durable enough to withstand the cooling and heating processes involved in the distillation of water.

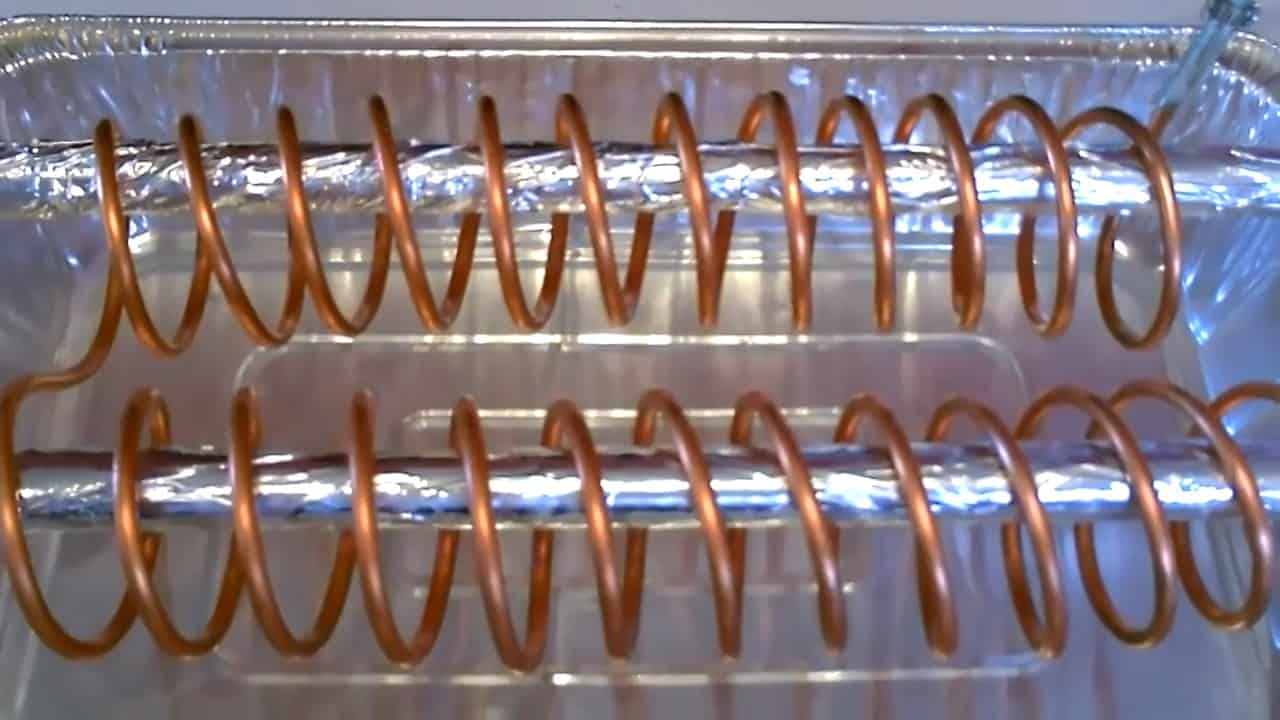

The soup can is used to create the coils for the copper tubing, while the aluminum foil is used to wrap the PVC pipes, which act as the condensation surface for the water droplets.

The 12V DC aquarium pump is crucial to facilitate the movement of water through the system, while the clear vinyl tubing connects the different components together.

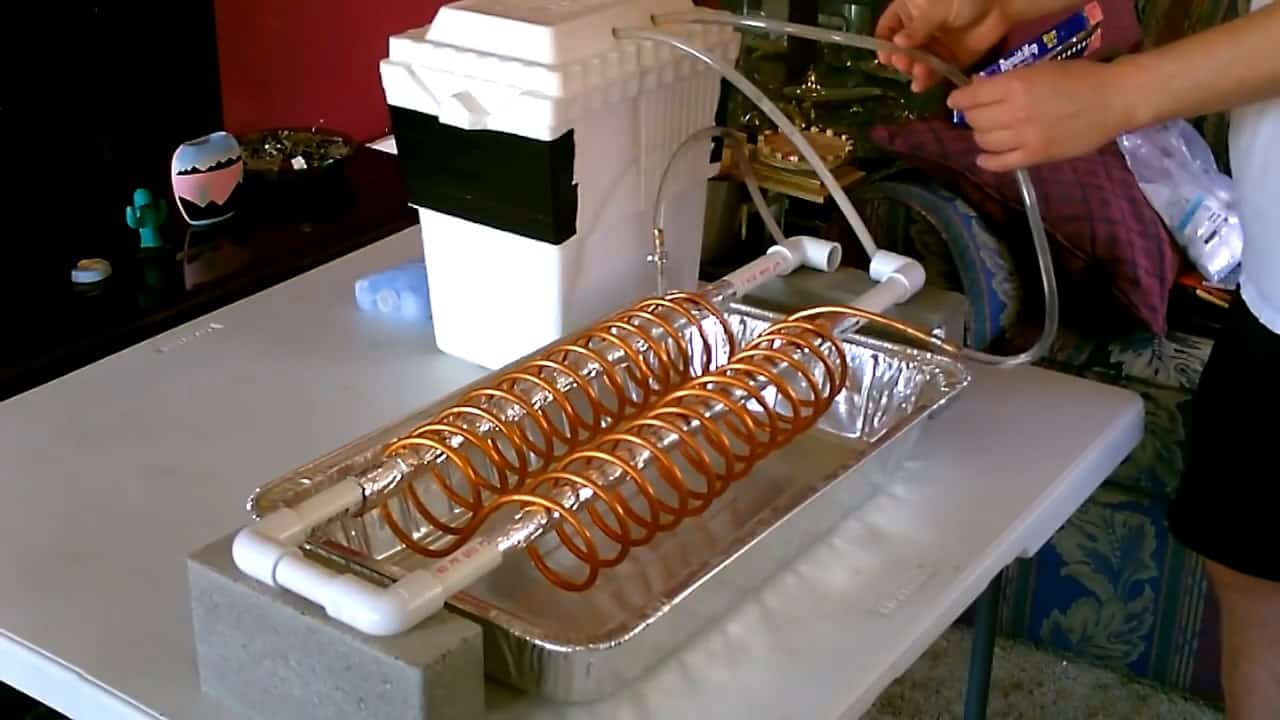

The aluminum tray is utilized to collect the distilled water, which is safe for consumption as it is free from contaminants and impurities. The small styrofoam cooler box serves as an insulated container to house the copper tubing and cooling water, ensuring optimal efficiency and effectiveness of the system.

STEP 2 : CONNECTING THE PIPES

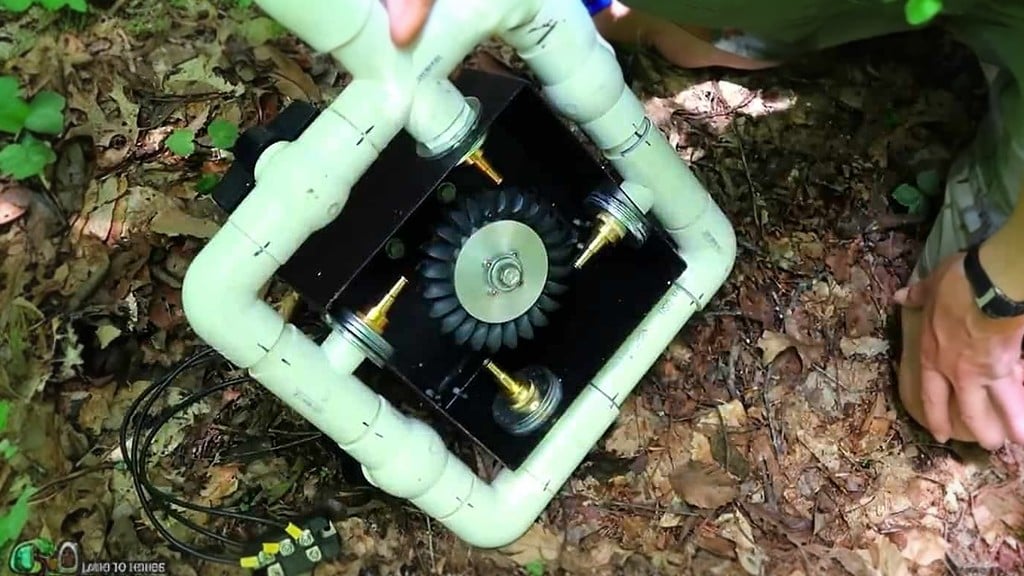

To construct the framework for the Atmospheric Water Generator, we begin by taking two half-inch PVC pipes and connecting them using two elbow joints.

The use of PVC pipes allows for flexibility in the design and ease of construction, while the elbow joints provide a secure and sturdy connection.

Once connected, the PVC pipes are wrapped in aluminum foil to enhance the condensation process and maximize the collection of water droplets.

The aluminum or glass tray is positioned beneath the PVC pipes to collect the distilled water that drips down from the coils. This tray serves as a crucial component of the system, as it allows for the collection of pure and clean water, free from any contaminants or impurities.

It is important to note that the positioning of the PVC pipes and the aluminum tray must be carefully considered to ensure optimal functionality.

The pipes should be positioned in a location where they are exposed to a sufficient amount of air to promote the collection of water droplets, while the tray should be placed in a way that allows for easy collection of the distilled water.

STEP 3 : DEW COLLECTION

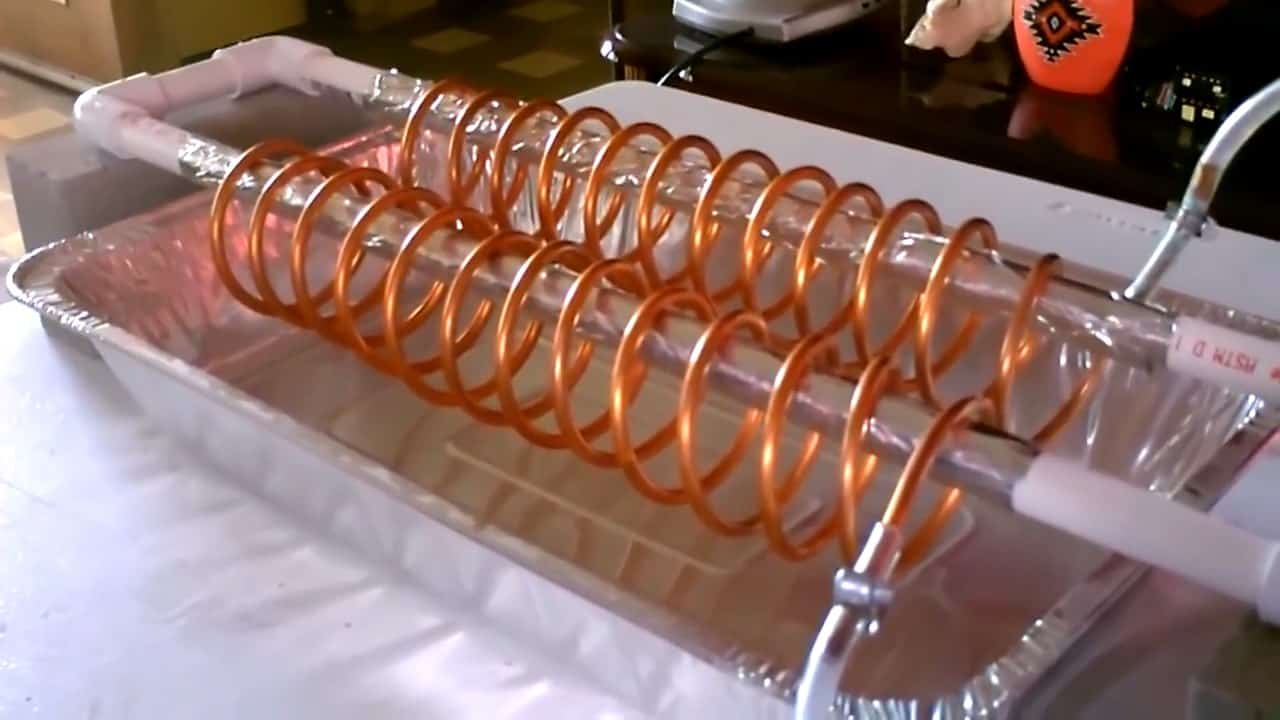

To commence the distillation process, cold water is pumped through two sets of coiled copper tubes. The copper tubes are carefully wrapped around a soup can to achieve the desired coiled shape.

This setup ensures that a large surface area is exposed to the air, which facilitates the condensation of water droplets.

As cold water flows through the copper tubing, the coils become significantly colder than the surrounding air. This temperature differential causes the air passing over the coils to lose its moisture content, resulting in the formation of dew on the coils.

The dew that forms on the coils is then collected by a drip pan, which is strategically placed beneath the coil to collect the distilled water.

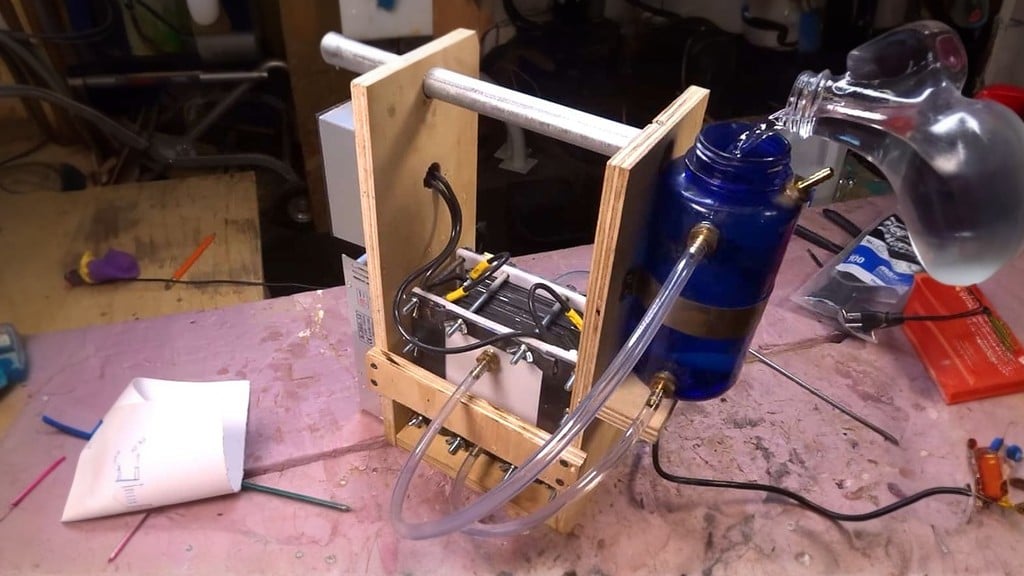

To facilitate the movement of water through the system, a clear PVC hose tube is clamped onto the copper coil, and a small 12V DC aquarium water pump is connected.

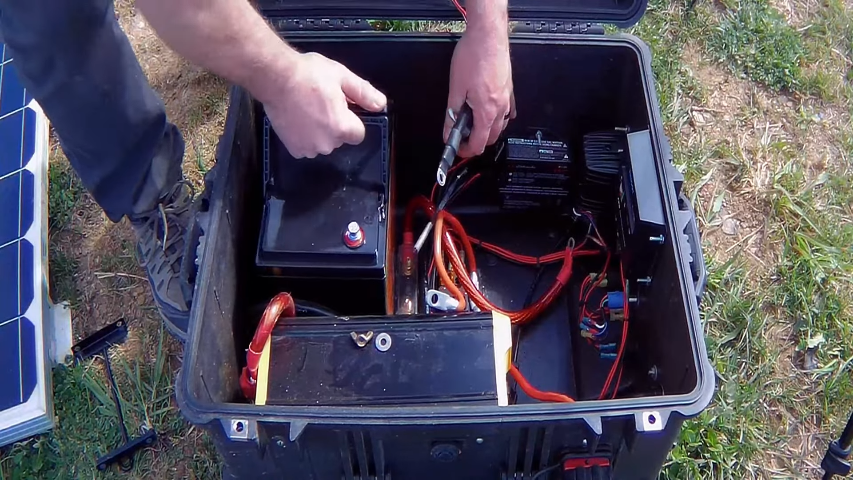

This pump is powered by either a battery or a solar panel, depending on the intended application and location of the Atmospheric Water Generator.

STEP 4 : ADDING A CHEST BOX AND A SUBMERGED PUMP

After the copper coil and pump system have been constructed, the next step is to submerge the water pump in a chest box or bucket filled with ice-cold water.

This step is crucial in ensuring that the water flowing through the copper coil is sufficiently cold, as the colder the water, the more efficient the condensation process.

Once the pump is submerged, it is started, and the water is forced out of the box cooler and sent through the coiled copper tubing.

As the water flows through the coils, it is cooled to below its dew point, which triggers the condensation process, resulting in the collection of water droplets on the coil’s surface.

It is important to note that the effectiveness of the system is dependent on the temperature of the water flowing through the copper coils.

If the water is too warm, it will not be sufficiently cold to trigger the condensation process, and water droplets will not form on the coil’s surface.

The efficiency of the Atmospheric Water Generator is directly proportional to the temperature of the cooling water and the humidity levels in the surrounding air.

The colder the water and the more humid the air, the faster the condensation process and the more distilled water is collected.

To further improve the efficiency of the system, the copper coils can be squeezed together, increasing the surface area exposed to the air and promoting the collection of water droplets.

The more coiled copper tubes included in the system, the greater the volume of water that can be extracted from the air.

It is essential to ensure that the coils are not too tightly squeezed together, as this can restrict the flow of water through the system and reduce its efficiency. Therefore, it is important to find the optimal balance between coil density and water flow rate to maximize the system’s output.

Image Credits : desertsun02