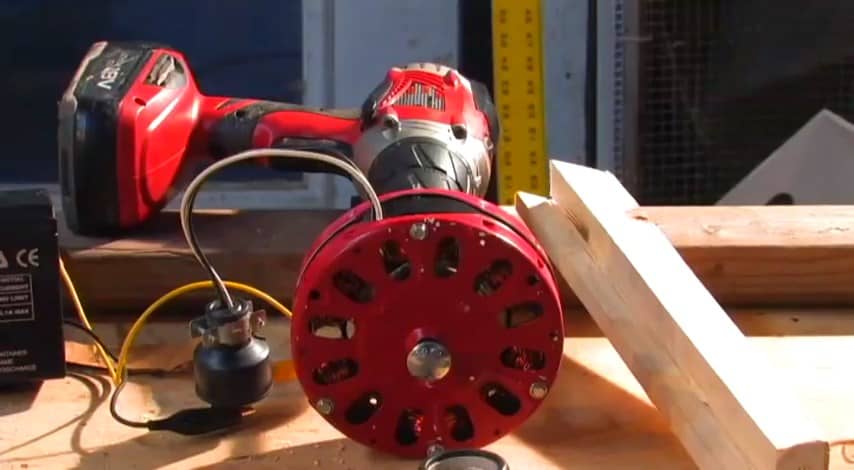

This article presents a comprehensive guide on how to transform an old ceiling fan motor into a single-phase alternator generator.

It is important to note that standard AC electric motors cannot be simply spun to generate electrical current; they require modification to achieve this purpose.

In this project, we utilize a ceiling fan motor, which can produce approximately 70 volts at one amp, equating to an output of around 70 watts.

By utilizing a bridge rectifier, we can convert the alternating current generated by the ceiling fan alternator into direct current, resulting in a consistent and reliable source of power.

This guide provides detailed instructions for the conversion process, enabling readers to successfully create their own single-phase alternator generator from an old ceiling fan motor.

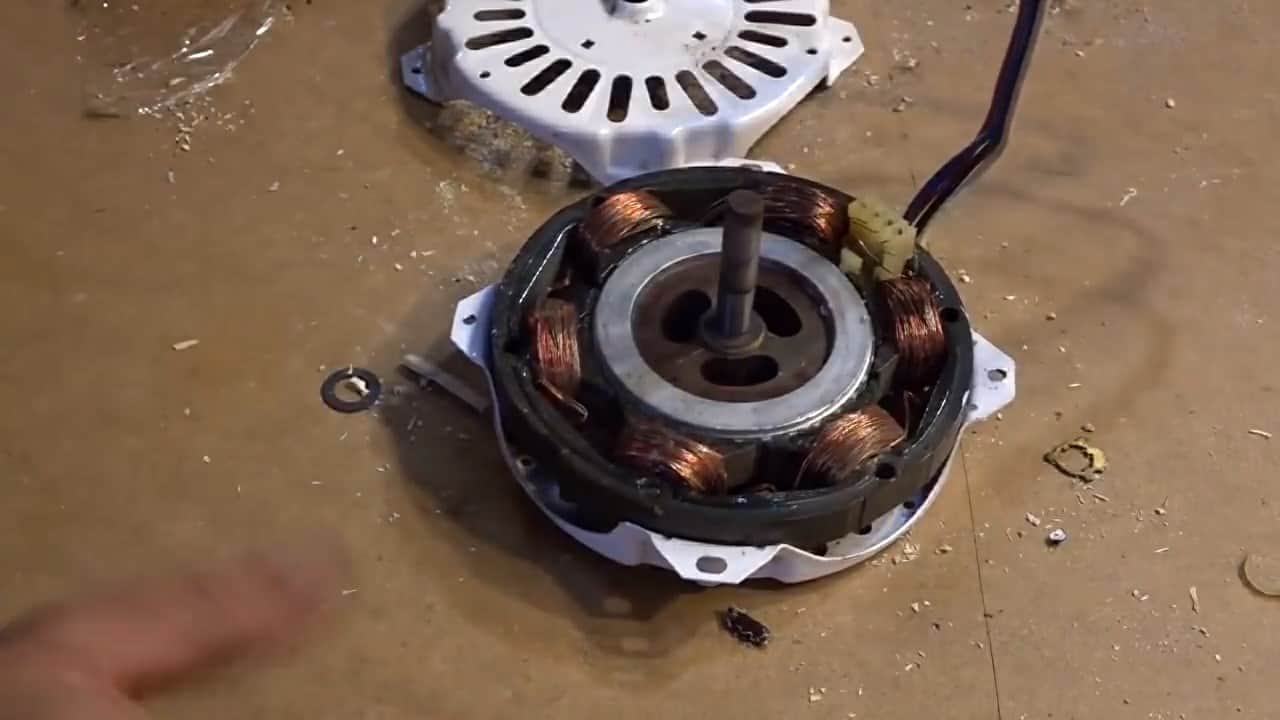

STEP 1 : REMOVING THE FAN COVER

To begin the conversion process, the cover of the fan must be removed, revealing the internal components of the motor.

Upon removal, one will find a squirrel cage rotor located at the center of the fan motor, surrounded by six coil windings.

These coil windings are positioned in both clockwise and anti-clockwise directions within the stator, serving as the critical components for generating electrical current.

STEP 2 : REMOVING THE ROTOR

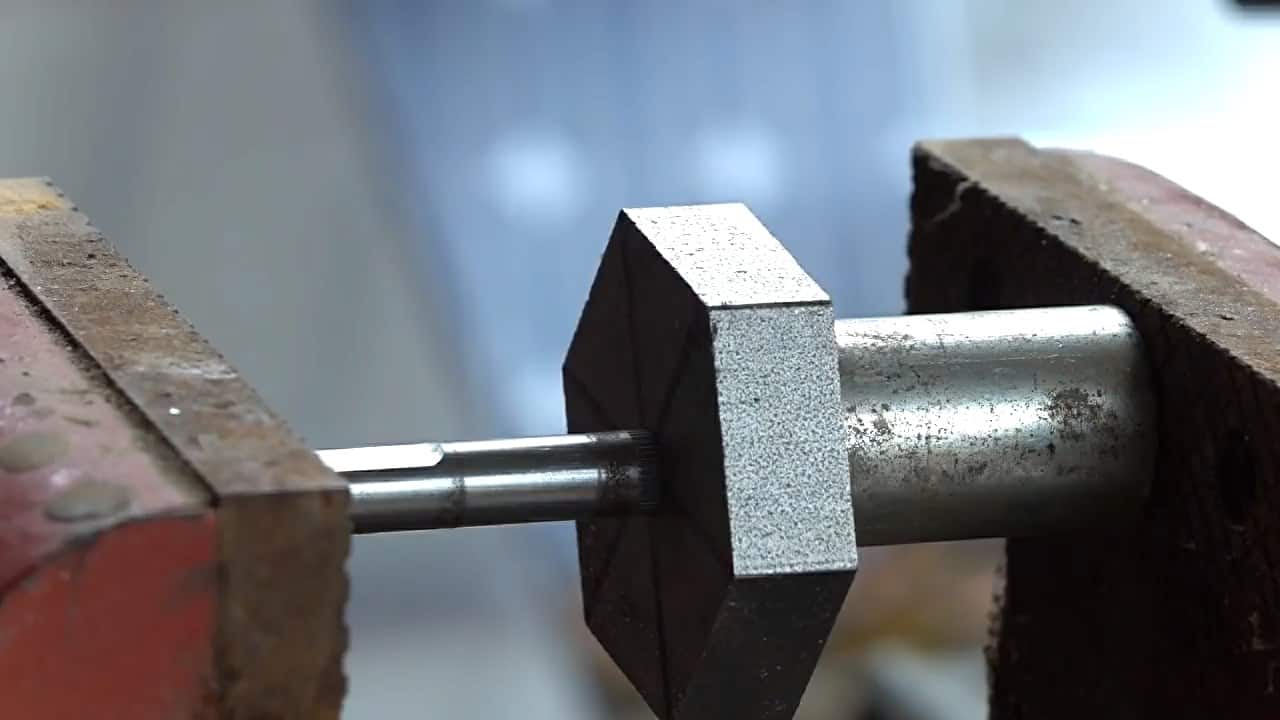

The next step is to remove the circular rotor from the threaded shaft to which it is attached. This process can be accomplished with the aid of a vice, which will securely hold the shaft and rotor in place.

The rotor should be positioned within the vice, with the shaft running through the center, enabling easy access for modification.

To remove the rotor from the shaft, an additional piece of pipe may be necessary to provide the necessary leverage.

This piece of pipe can be used to press against the rotor, gradually pushing it away from the rod until it can be safely removed.

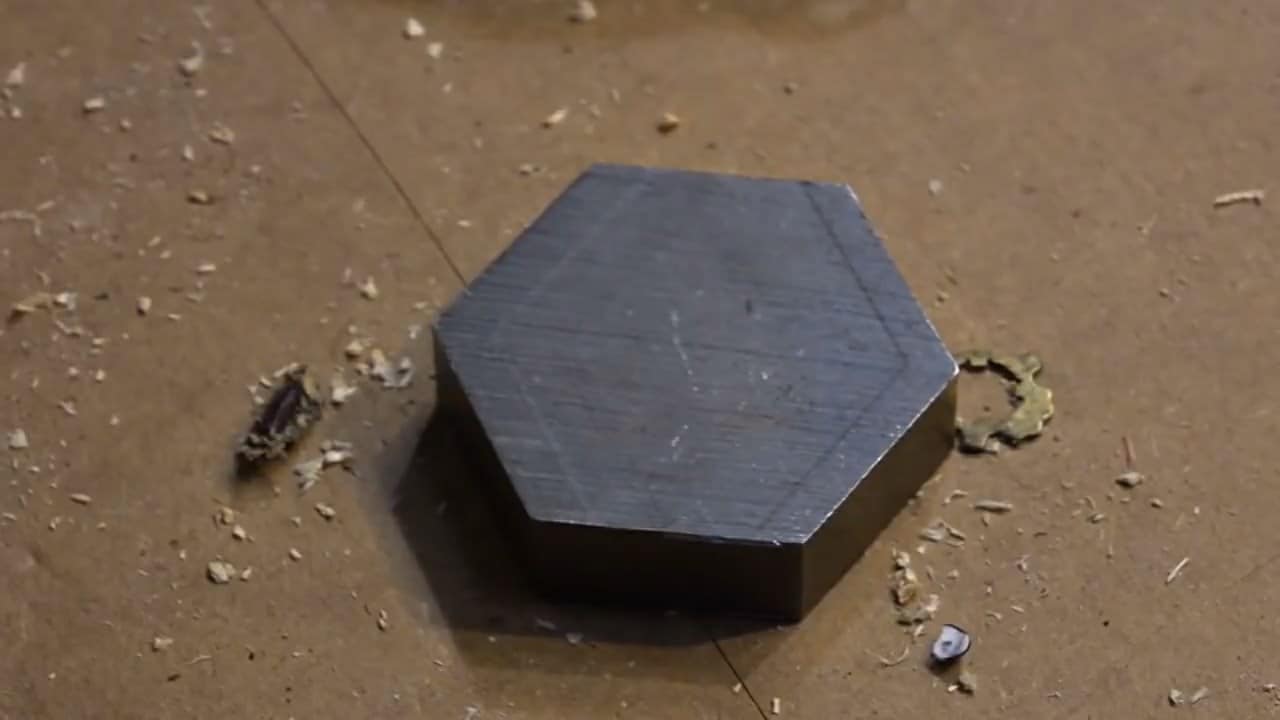

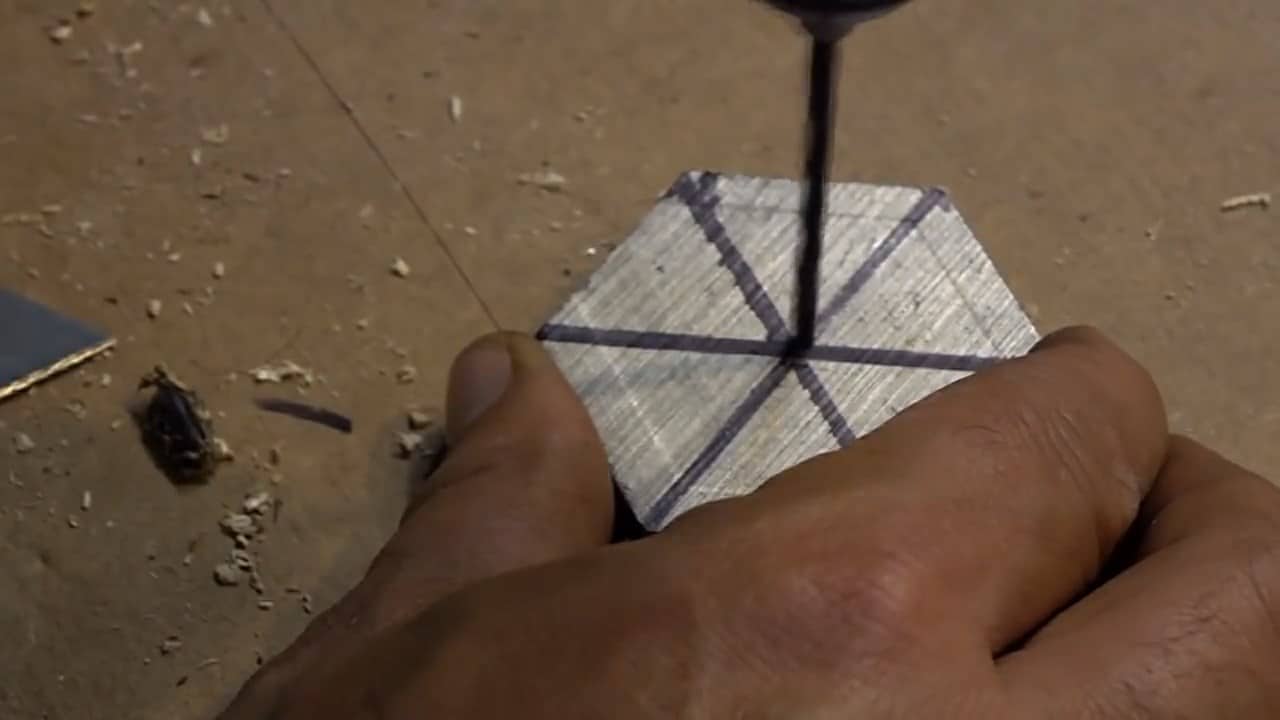

STEP 3 : ADDING HEX STEEL BAR TO THE ROTOR

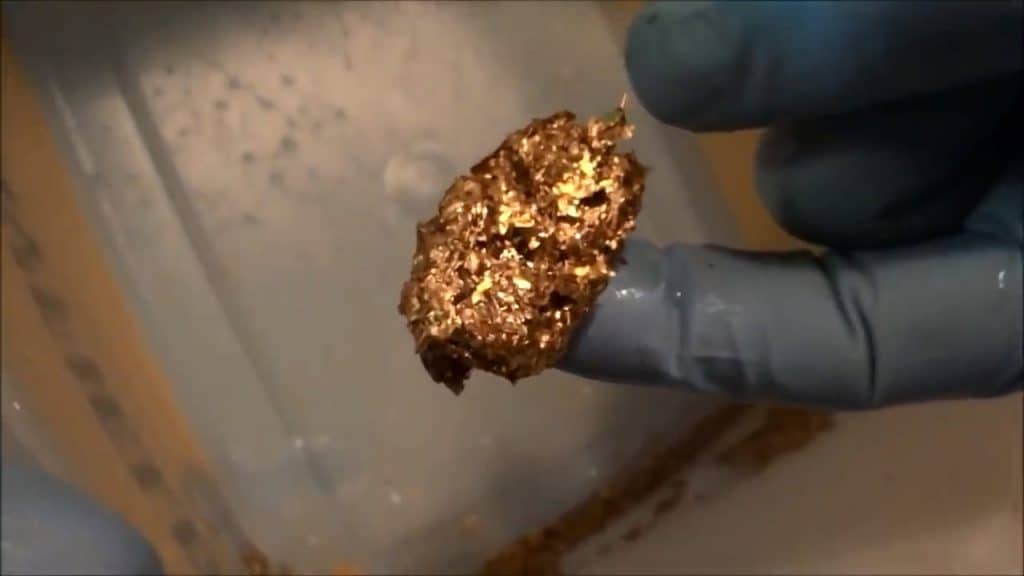

The subsequent stage in the process of converting an old ceiling fan motor into a single-phase alternator generator entails placing magnets along the sides of the hex bar.

This step is crucial, as magnets serve as a critical component in the generation of electrical current. In this step, six one-half-inch neodymium or rare earth magnets are placed along the six sides of the hex bar.

It is important to position the magnets in a manner that the poles oppose each other. This opposing positioning of the magnets will allow for optimal magnetic field interaction, which is crucial in generating maximum electrical output.

Using an eighth-inch drill bit, a hole is carefully drilled through the center of the hex bar.

The drilled hole serves as a crucial point of attachment for securing the hex bar onto the shaft.

Once the hole has been drilled, the hex bar is inserted through the shaft and snugly fitted around the threaded area.

STEP 4 : PLACING MAGNETS ALONG THE SIDES OF THE HEX BAR

Now it’s time to add some magnets to our modified rotor! Take six neodymium or rare earth magnets that are half an inch in size and place them along the six sides of the hex bar.

Make sure to position the magnets in such a way that the poles oppose each other.

To keep the magnets securely in place, wrap them with a bit of tape or glue. This will prevent them from moving around during operation and ensure they stay optimally aligned with the hex bar.

STEP 5 : ALIGNING THE ROTOR WITH THE STATOR

Carefully place the modified rotor, with the hex bar and magnets, in the middle of the stator. Make sure to align them so they fit tightly and snugly together.

Once in place, bolt the outer screen back onto the motor to secure everything in place. If you want to increase the power output of your alternator generator, you can also add a second set of magnets.

This will enhance the magnetic field of the rotor, bringing it closer to the coils on the outside and increasing the overall voltage output.

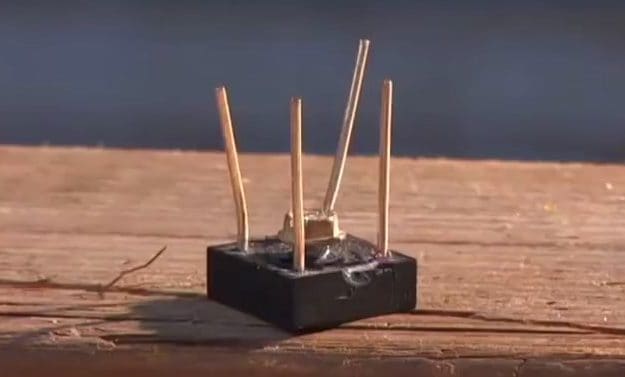

STEP 6 : CONVERTING AC CURRENT

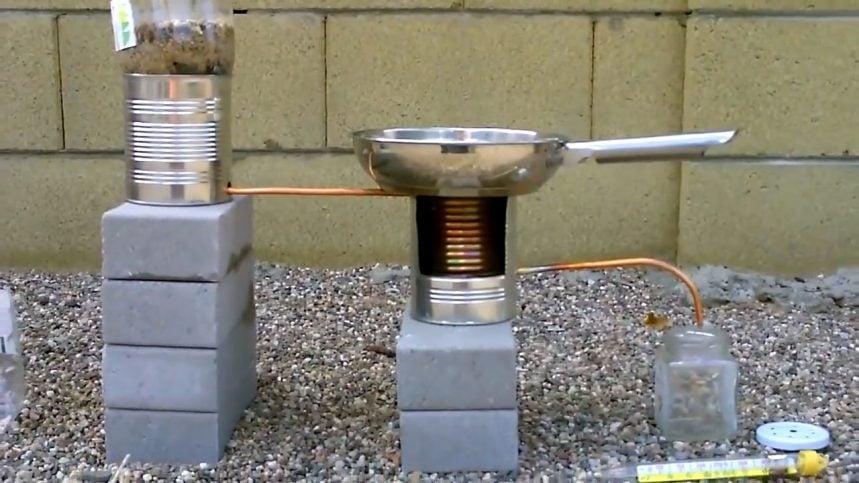

The final step in converting an old ceiling fan motor into a single-phase alternator generator involves converting the alternating current generated by the motor into direct current. To achieve this, we will use a bridge rectifier.

The bridge rectifier has four poles, two of which are used for connecting the alternating current, while the other two poles are used for positive and negative DC power.

By connecting the alternating current to the rectifier, we can convert the electrical output of the alternator generator into direct current, which can be used to power a wide range of DIY projects.

In conclusion, converting an old ceiling fan motor into a single-phase alternator generator can be a great DIY project for those looking to create a sustainable and reliable source of energy. To achieve this, we have covered the following steps.

First, we removed the cover of the fan and detached the rotor from the threaded shaft. We then replaced the rotor with a two-inch hex steel bar and added neodymium or rare earth magnets along the six sides of the hex bar.Next, we aligned the modified rotor with the six coil windings inside the stator and bolted the outer screen back onto the motor. Finally, we used a bridge rectifier to convert the alternating current generated by the ceiling fan alternator into direct current.

Image Credits : GREENPOWERSCIENCE