The need for sustainable and renewable energy sources has become increasingly important in recent times.

In this regard, one promising option is the utilization of hydroelectric power generated from flowing water in rivers or streams.

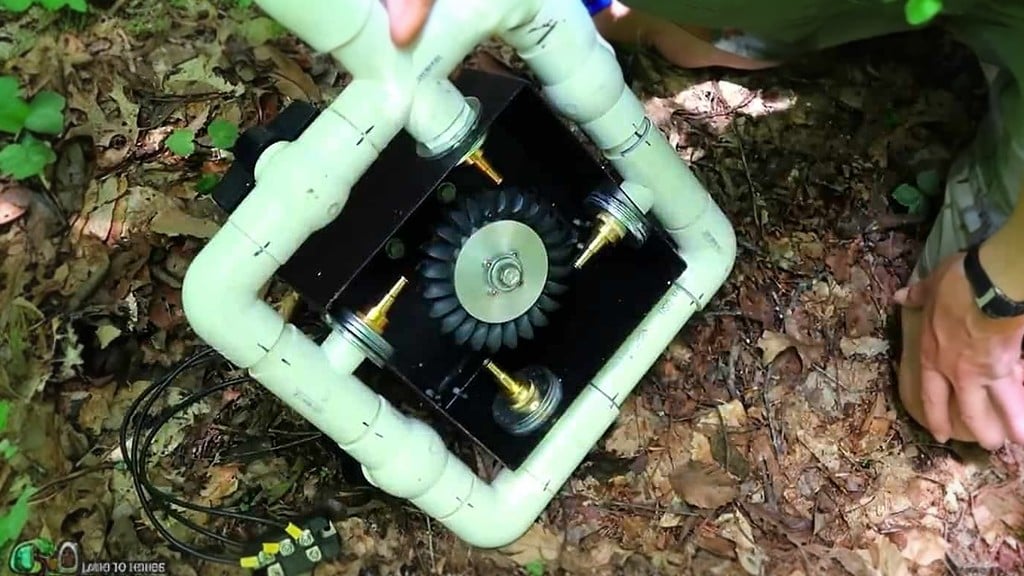

The Archimedes Screw Turbine is a type of micro-hydro turbine designed to harness the energy of flowing water and convert it into usable power.

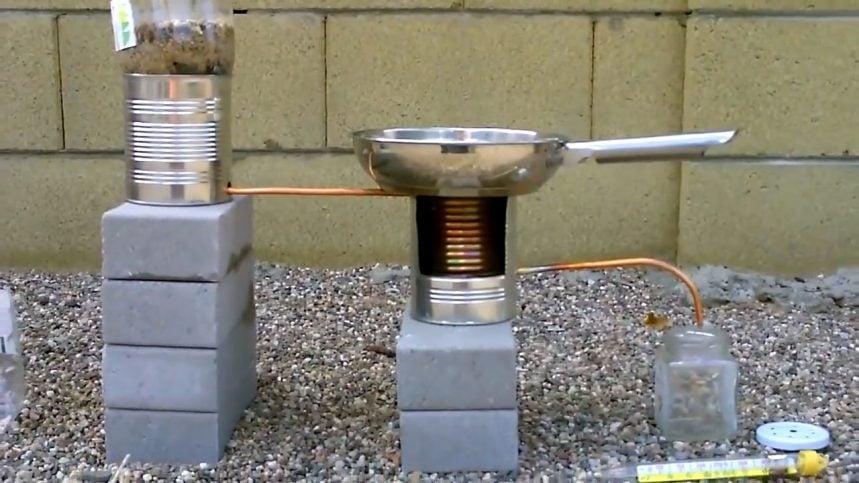

This DIY project outlines the construction of an Archimedes Screw Turbine using PVC parts, which is an affordable and easily available material.

The turbine functions by utilizing a screw mechanism, which rotates as water flows through the pipe. The rotation of the screw, in turn, drives a shaft connected to a pulley system and a motor that generates electricity.

STEP 1 : FARMING AUGER

The first step is to gather the necessary materials, including a 5-foot farming auger and a 6-inch diameter PVC pipe.

The farming auger will serve as the main component for harnessing the kinetic energy of the flowing water, while the PVC pipe will be used to direct the water flow through the auger.

To begin, insert the farming auger inside the PVC pipe and position it at a specific angle in the creek or river where the water flows consistently.

The angle of the auger is critical in determining the amount of energy that can be generated, with the ideal angle typically ranging between 20 to 30 degrees.

It is also essential to ensure that the auger is submerged below the water level to maximize efficiency.

As water flows into the pipe, it fills up the auger, causing it to become heavy and rotate due to the weight of the water.

The rotation of the auger is responsible for driving a shaft that is connected to the end of the PVC pipe. This shaft is crucial in transmitting the rotational energy of the auger to a pulley system that ultimately generates electricity.

STEP 2 : SMOOTHENING THE FARMER AUGER

In the second step of building an Archimedes Screw Turbine, it is essential to smoothen the edges of the farming auger to ensure that it can rotate smoothly without any friction.

To smoothen the edges of the farming auger, use an old belt sander and carefully shave off any rough or uneven areas.

Once the edges are smoothened, it is advisable to test the auger’s rotation inside the PVC pipe to ensure that it is moving freely and without any obstructions.

STEP 3 : OPENING UP SPACE

In the third step of building an Archimedes Screw Turbine, an angle grinder is used to create a partial split down the middle of the PVC pipe.

To begin, use an angle grinder to make a partial split down the middle of the PVC pipe.

The split should be wide enough to create additional space inside the pipe, but not so wide that it weakens the structural integrity of the PVC pipe.

Next, use separator nuts to expand the interior space of the pipe. The separator nuts are positioned along the split and tightened to create more space for the auger to rotate freely.

This process allows the auger to move smoothly without any obstructions.

After creating additional space, heat the top of the PVC pipe using a heat gun to make it more pliable. Then, attach two spacer boards on either side of the opening and use a C-clamp to gently stretch the heated area.

STEP 4 : ADDING BOARDS

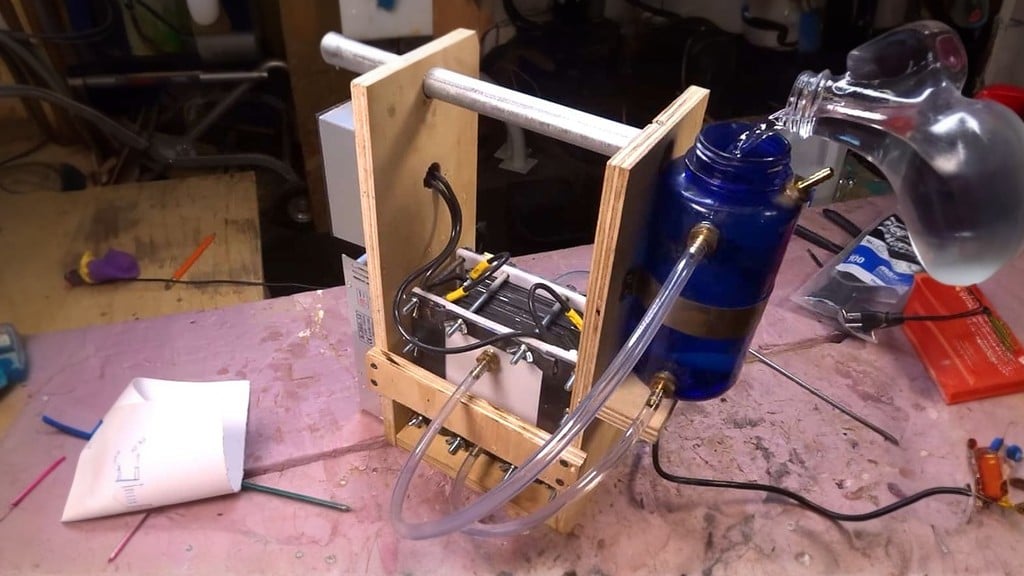

In the fourth step of building an Archimedes Screw Turbine, two three-quarter-inch thick boards are attached to either side of the PVC pipe using carriage bolts.

These boards provide additional support and create enough space for the smooth installation of the auger within the pipe, ensuring its optimal performance when generating power from the flowing water.

To begin, position the PVC pipe between the two boards and align them to ensure that the pipe is centered. Once the pipe is centered, drill holes through the boards and the pipe at regular intervals to accommodate the carriage bolts.

Next, insert the carriage bolts through the holes and tighten them using nuts. This process ensures that the boards are securely attached to the PVC pipe and can provide the necessary support to the auger.

STEP 5 : SECURING BOARDS

The fifth step in building involves inserting all-thread rods that are eight and a quarter inches in length through the holes in the boards, and securing them in place using washers and non-locking nuts.

To begin, insert the all-thread rods through the holes in the boards and the PVC pipe. Then, place a washer on each end of the rod, followed by a non-locking nut.

Tighten the nuts using pliers until they are snug, but not so tight that they damage the PVC pipe or the boards.

This secure attachment provides stability to the turbine by preventing any wobbling or misalignment that could affect its performance.

Image Credits : Land to House