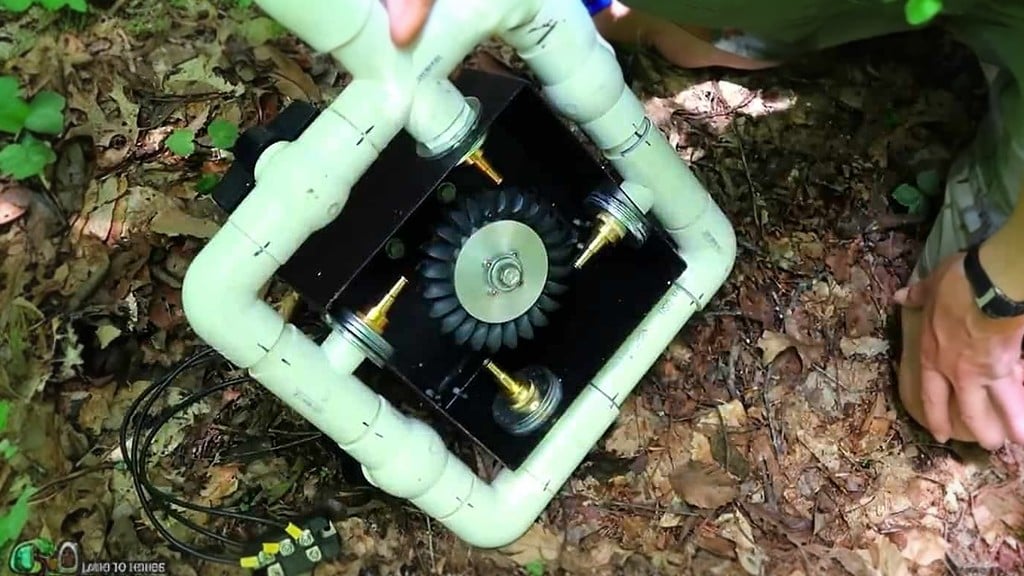

This project is focused on building a river pump that allows you to pump water from a nearby river or creek without the need for any external power source.

This system operates using a circular tube that utilizes the flow of the river to create air pressure and push the water further.

As the pump rotates, it gulps both air and water, and through this process, it is able to extract water from the river and deliver it through a hose system that can be directed to any location as per your requirement.

The design of this pump is simple yet effective, and it utilizes readily available materials such as PVC pipes, reducers, and tubing.

The pump is made up of a cone-shaped PVC structure, with a window screen attached to the back to prevent debris from entering the system.

At the front of the pump, there are four PVC blades that are designed to spin as the water flows through the system.

To utilize this river pump, you need to identify a nearby river or creek that has a steady flow of water.

This system relies on the movement of water to function effectively, so it is essential to select a location that provides a consistent flow of water throughout the year.

Once you have found a suitable water source, you need to locate a spot that is deep enough to support the pump.

STEP 1 : MATERIALS REQUIRED

To build this river pump, you will need a few basic materials that are readily available at most hardware or plumbing stores. The following are the essential parts required for this project:

- A 3-inch to 4-inch reducer: This reducer is used to connect two pipes of different sizes, and it is necessary for creating the cone-shaped structure that makes up the body of the pump.

- A 4-inch to 6-inch reducer: Similar to the first reducer, this component is used to connect two pipes of different sizes.

- 40-foot, 3/8 inch tubing: This tubing is an essential component of the pump, and it is used to transfer the water from the pump to the desired location.

- 3-inch socket to thread/cap: This component is used to seal the bottom end of the pump and ensure that water is pulled in through the front blades.

- Garden hose adapter: This component is used to connect the pump to a garden hose, allowing for the water to be directed to the desired location.

- Quick-release couplings: These couplings are used to connect the various PVC pipes that make up the pump, allowing for easy assembly and disassembly of the system.

- Six, four, two-inch pipes: These pipes are used to create the fan blades at the front of the pump, and they are essential for generating the air pressure necessary to move water through the system.

STEP 2 : CONNECTING THE PVC PIECES

To begin constructing the cone-shaped structure of the river pump, you will need to cut the PVC pipes into four pieces using an angle grinder.

Once the PVC pipes have been cut into four equal pieces, they can be connected together using a PVC cement solvent.

To assemble the cone-shaped structure, start by connecting two pieces of PVC pipe using the cement solvent.

Next, attach a reducer to one end of the connected pipes and then attach another piece of PVC pipe to the other end of the reducer.

Repeat this process with the remaining pieces of PVC pipe and reducers until you have created a cone-shaped structure that steps down as it goes.

STEP 3 : ADDING A WINDOW SCREEN

To ensure the efficient operation of the river pump, a window screen should be added to the back of the cone-shaped structure.

The screen serves as a shield, preventing debris and other particles from getting caught in the system and causing blockages or malfunctions.

This design feature is essential in maintaining the streamlined flow of water through the pump.

When choosing a window screen, it is important to select one that is durable and able to withstand exposure to the elements.

The screen should be securely fastened to the back of the cone-shaped structure to prevent it from becoming dislodged during operation.

Additionally, it is important to ensure that the design of the pump is streamlined and free of any unnecessary protrusions or sharp edges. This will help to reduce drag and turbulence in the water flow,

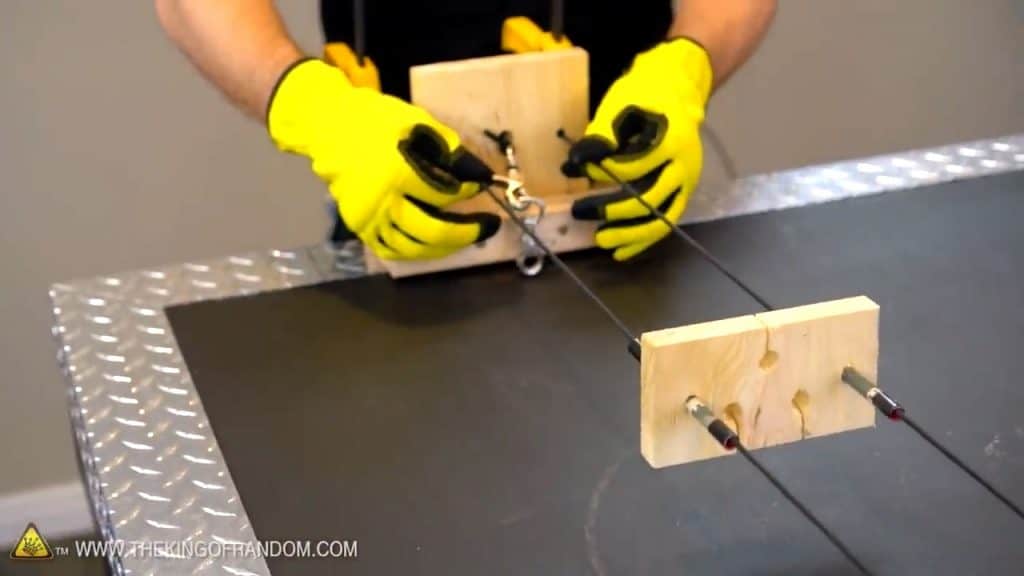

The cap at the end of the cone-shaped structure of the river pump needs to be attached to a swivel piece. This swivel piece is essential for directing the flow of water from the pump to the desired location.

The swivel piece needs to be able to rotate freely on top of the cap, allowing the hose to be directed in any direction without causing any strain on the system.

To attach the swivel piece to the cap, a metal component is used. The hose tightens into this metal swivel piece and gets locked down, ensuring a tight seal and preventing any leaks or loss of pressure.

STEP 4 : BUILDING THE FAN BLADES

The next step in constructing the river pump is to create the fan blades that are essential for generating the air pressure necessary to move water through the system.

To create the fan blades, the PVC pipe is cut into four equal pieces that are 8 inches tall.

These pieces will be bolted onto the swivel piece along with the cap at the end of the cone-shaped structure.

Once the fan blades have been attached to the swivel piece, water flows in and hits the blades that are attached to the rotating swivel.

The force of the water hitting the blades causes the swivel piece to move and rotate, creating air pressure that pushes the water further through the system.

This rotational movement also causes the water to hit the next set of blades in line, creating a continuous flow of water through the system.

It is important to ensure that the fan blades are evenly spaced and securely fastened to the swivel piece to prevent any imbalances or disruptions in the system.

Additionally, the blades should be angled and shaped in a way that maximizes their ability to generate air pressure and move water efficiently.

STEP 5 : CONNECTING THE HOSING TUBE

After the fan blades have been attached to the swivel piece and the cap at the end of the cone-shaped structure, the next step in constructing the river pump is to attach the end piece to the PVC cone that was created earlier.

This end piece serves as the outlet for the water, allowing it to be directed to the desired location.

Once the end piece has been attached to the PVC cone, the next step is to get the 40-foot hose tubing inside the pipe and attach it to the swivel end.

Once the hose tubing has been attached to the swivel end of the river pump, the next step is to wrap the 40-foot hose around the pump.

It is important to wrap the hose in a way that ensures it is able to pick up water once it hits the swivel end, allowing for a steady flow of water through the system.

To properly wrap the hose, start by positioning the pump along the direction of the flow of the river or creek. This will ensure that the water is flowing directly into the inlet at the front of the pump.

Next, begin wrapping the hose around the pump in a spiral pattern, ensuring that each loop of the hose is tight and secure.

As you wrap the hose, make sure that it is positioned in a way that allows it to easily pick up water from the swivel end.

The hose should be wrapped in a way that allows it to flow smoothly and evenly, with no kinks or disruptions that could hinder the flow of water.

STEP 6 : PLACING THE PUMP ALONG THE FLOW

Once the hose has been securely wrapped around the pump, the next step is to connect a garden hose to the swivel end of the pump. This garden hose serves as the outlet for the water, allowing it to be directed to the desired location.

To connect the garden hose, simply attach one end of the hose to the swivel end of the pump and the other end to a nozzle or other attachment for directing the flow of water.

Once the garden hose has been attached, it is important to place the river pump along the direction of the flow of the river or creek. This will ensure that the water is flowing directly into the inlet at the front of the pump.

Image Credits : Land to House