This project goes over the conversion of an old three-way refrigerator unit from an RV into an alternative power Off-grid Dual refrigeration system that uses no electric power.

This can be really useful in case of a power outage or SHTF situation when you need to keep your food or vegetables fresh.

STEP 1 : REMOVING THE COMPONENTS OF THE OLD REFRIGERATOR

The first step is to strip the fittings on the backside of the fridge and remove the ammonia system. Once this is completed, the inside of the refrigerator must be thoroughly cleaned to ensure it is free of any contaminants.

This project incorporates two different methods for cooling the refrigerator system. Firstly, the cooling effect is induced by bringing down the temperature of the water that circulates through the system, thereby cooling the box.

The second method involves installing an evaporative cooling system. In this approach, two pipes coming from the water source are placed around the edges of the box, and cotton sheets are wrapped around the sides.

The water cascades down the sheet, creating an evaporative effect, which cools the refrigerator.

STEP 2 : CONNECTING THE FISH TANK PUMP

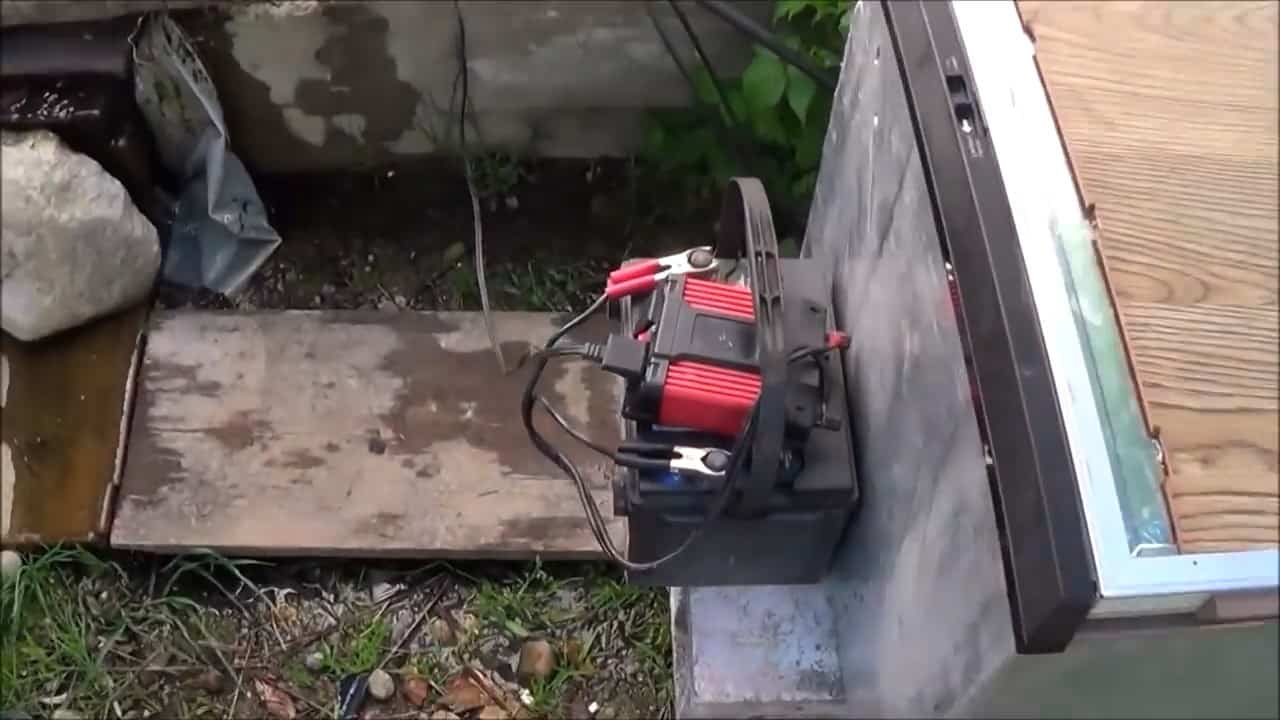

To power the off-grid dual refrigeration system, an inverter and a battery are attached to the fridge, which are connected to a 25W solar panel.

A wire from the inverter is then connected to an 8W electric fish tank pump, which circulates water throughout the system.

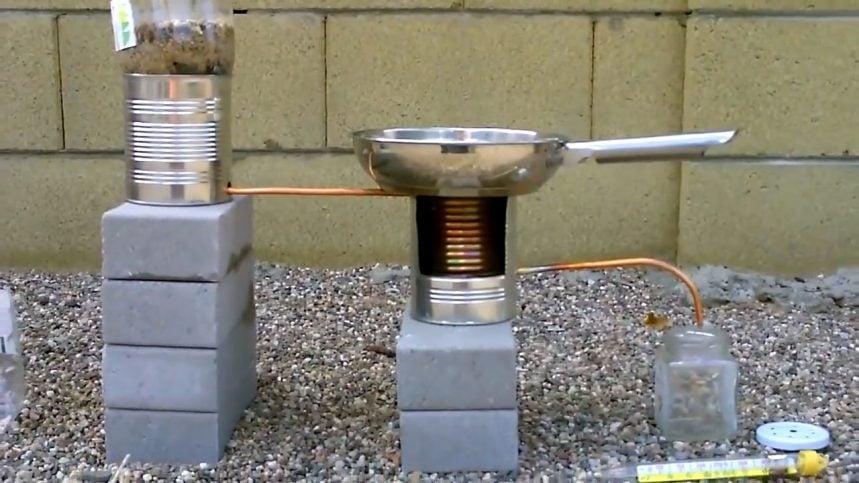

The water from the pump flows underneath and up inside to the lid of the fridge to the condenser coils, which facilitate the cooling process.

The water then recirculates back into the original storage tank, such as a well or water tank, where it is continually replenished.

STEP 3 : ADDING TWO POLY TUBING COILS

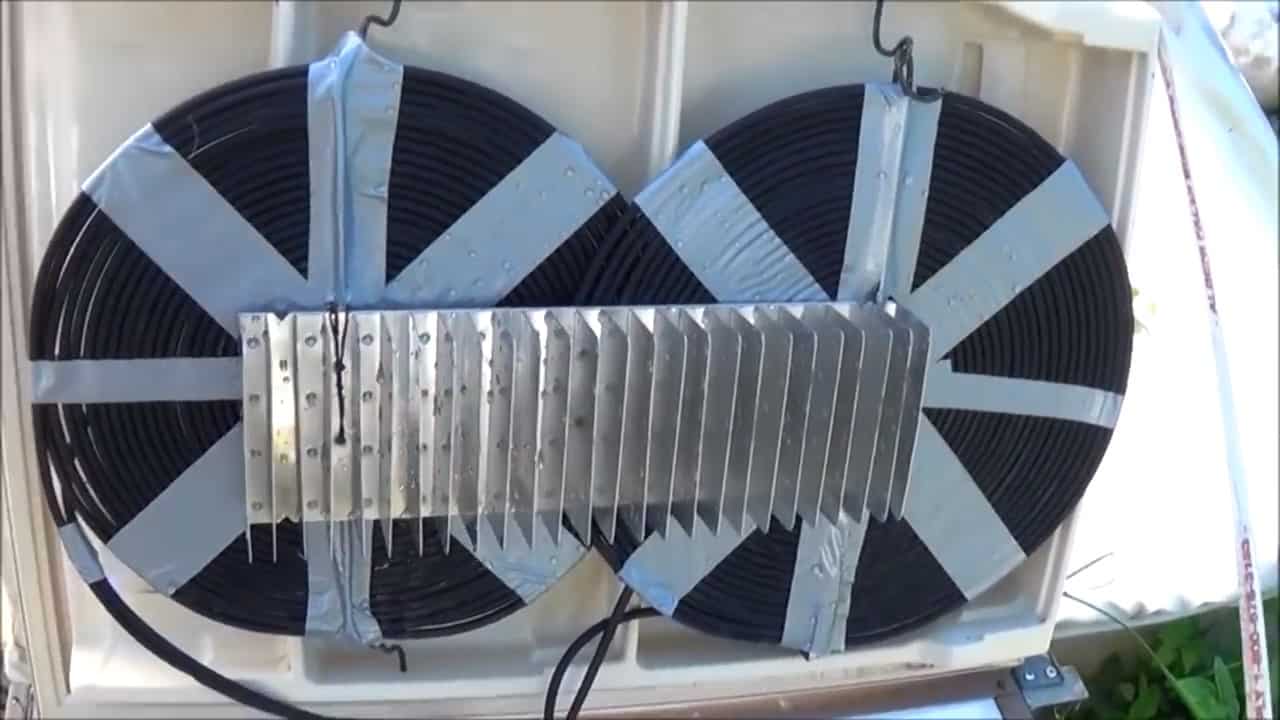

To optimize the off-grid dual refrigeration system, the fridge is designed in a chest freezer style, rather than an upright style, which is more efficient in preserving cold air and reducing energy consumption.

Inside the fridge, there are two poly tubing coils, which are attached to an old heat sink that was already present in the fridge. The coils are approximately 100ft long and are attached to the top of the fridge.

As water flows through the tubing, it absorbs heat from the fridge’s interior and transfers it to the heat sink, which then dissipates the heat into the surrounding air.

The tubing then cools down and absorbs more heat from the fridge.

STEP 4 : INDUCING AN EVAPORATIVE COOLING EFFECT

To further enhance the efficiency of the off-grid dual refrigeration system, the next step is to incorporate an evaporative cooling system.

This is achieved by installing aluminum U channels across all edges of the fridge. The U channels are designed to hold cotton material inside of them, which will facilitate the evaporative cooling effect.

The water coming out of the outputs from the coils rushes into the channel, which then wicks out into the cotton cloth and runs down the cloth by gravity.

As the water evaporates from the cloth, it cools the air around it, creating an evaporative cooling effect that helps to further lower the temperature inside the fridge.

The U channels are also interconnected through a bent garden hose at the corners, allowing any excess water flow to transfer to the next channel.

By evenly distributing the water across the cotton cloth, this step ensures that the evaporative cooling effect is consistent throughout the entire fridge.

To further optimize the evaporative cooling system of the off-grid dual refrigeration system, the U channels installed on the corners of the fridge are interconnected through a bent garden hose.

This design is intended to facilitate the transfer of any excess water flow in the channel to the next channel, ensuring an even distribution of water across the cotton cloth.

The interconnected U channels are also designed to create a continuous water flow, which is essential in maintaining the effectiveness of the evaporative cooling system.

By transferring excess water flow to the next channel, this design helps to prevent the buildup of stagnant water in any particular channel, which can impede the evaporative cooling effect.

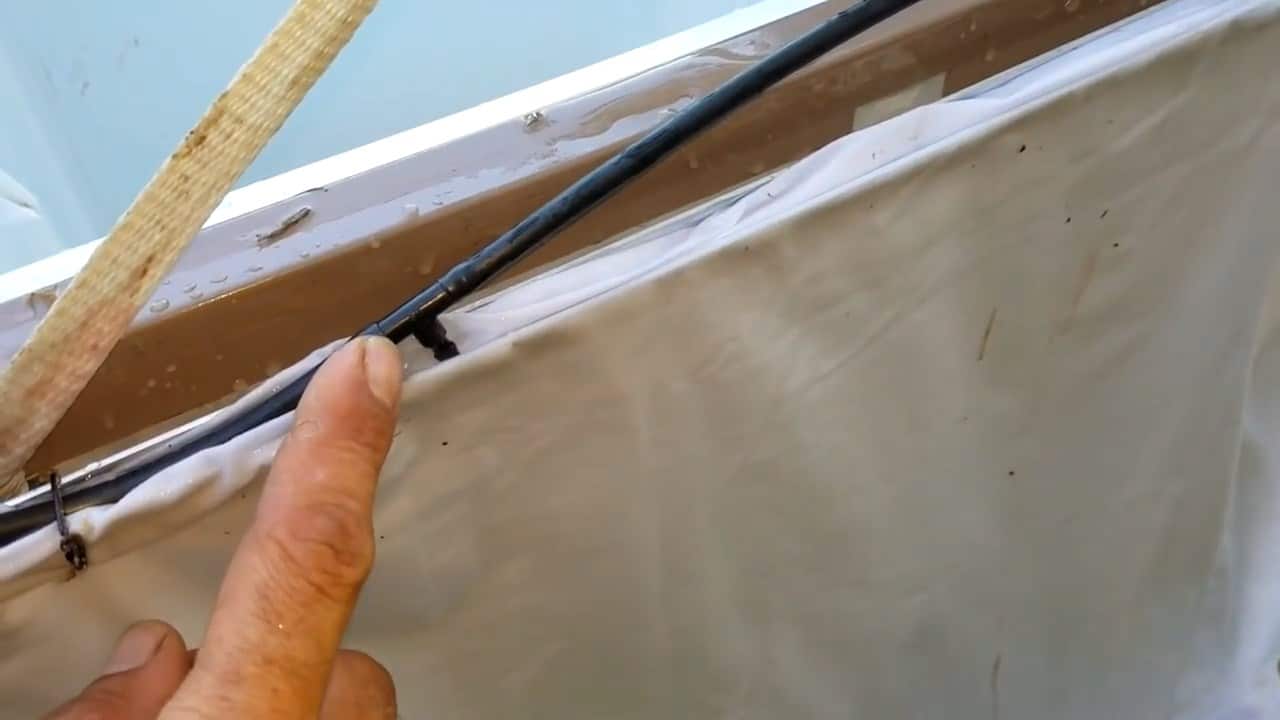

After installing the U channels and the cotton material, the next step in optimizing the evaporative cooling system of the off-grid dual refrigeration system is to stretch the cotton sheets around the box.

The sheets are then tucked down into the channels all the way around under the wires so that the wires hold the channels up and hold the sheet up inside the channel.

To ensure an even flow of water through the cotton sheets, a tee is installed to allow water to come from both sides of the channel and leak into the sheet.

This design ensures that the cotton sheets are evenly saturated with water, facilitating an optimal evaporative cooling effect throughout the entire fridge.

It is also essential to ensure that there is an air gap between the cotton sheets and the refrigerator box.

This gap is designed to prevent direct contact between the cold surface of the refrigerator and the cotton sheets, which could impede the evaporative cooling effect.

By maintaining a sufficient air gap, the cotton sheets can effectively absorb heat and moisture from the air, resulting in a more efficient cooling process.

By repurposing an old three-way refrigerator unit from an RV and incorporating innovative design elements such as poly tubing coils, an evaporative cooling system, and interconnected U channels, this system is capable of providing consistent cooling even in challenging off-grid environments.

The use of solar power to drive an electric fish tank pump and recirculate water through the system further minimizes energy consumption, making this system an eco-friendly and cost-effective solution for preserving perishable items