This article details the construction of a Straw Style Survival Water Filter, which is a small and lightweight device ideal for use in scenarios such as hiking, camping, and emergency situations.

The filter is highly effective at purifying both rainwater and tap water, while also effectively removing disease-causing water contaminants. With proper maintenance, this filter has the potential to last for several years.

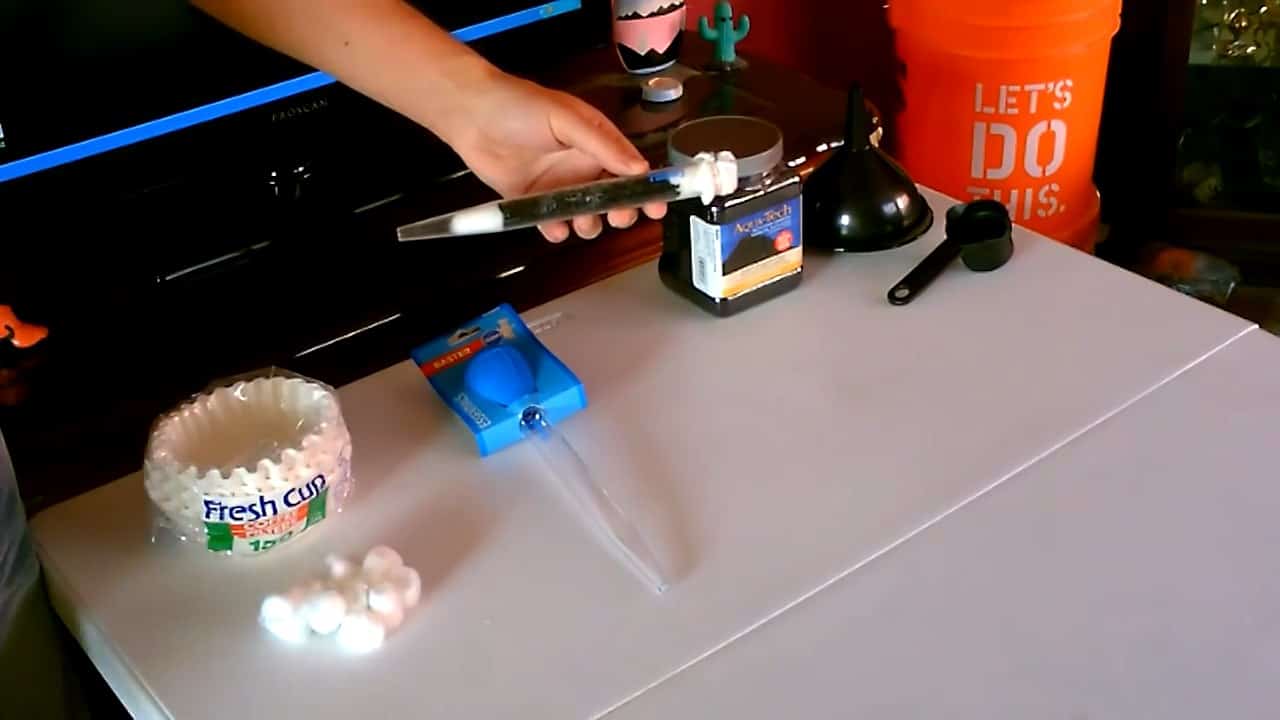

STEP 1 : MATERIALS REQUIRED

To assemble this water filter, you will require a few simple materials that are widely available at local stores and aquarium supply shops.

These materials include a turkey baster, cotton balls, coffee filters, and activated carbon.

It is recommended that you purchase activated carbon that is rated to last for at least five months with regular usage. This ensures that your water filter remains effective over an extended period.

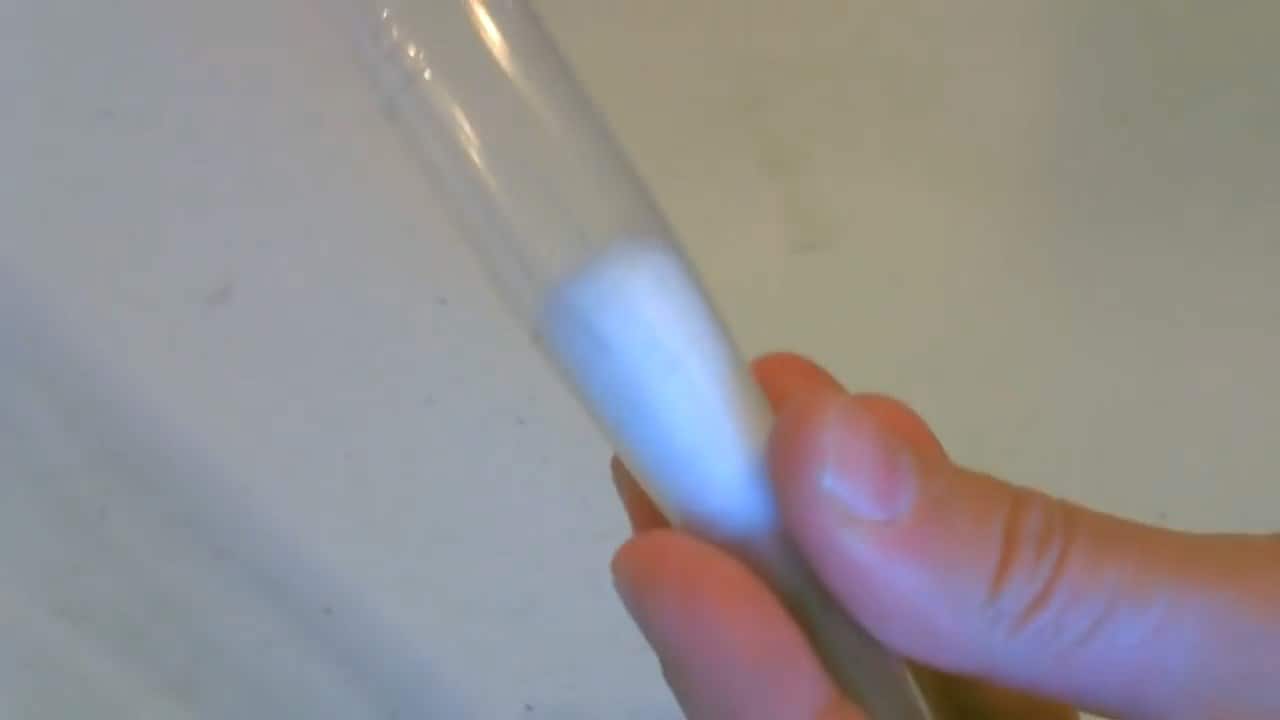

STEP 2 : ADDING COTTON BALL AND ACTIVATED CARBON

First, take a clean and dry cotton ball and gently push it down into the turkey baster. This will serve as a barrier to prevent the activated carbon from escaping.

Rinse the activated carbon thoroughly by running it under tap water until the water runs clear. This step is critical to remove any dust or debris from the activated carbon, ensuring that it is clean and ready for use.

Pour the rinsed activated carbon into the turkey baster, filling it all the way to the top. Leave a little bit of space at the top to ensure that water can flow through the filter.

STEP 3 : ADDING COFFEE FILTER

Once you have the activated carbon and cotton balls in place, it’s time to add the coffee filter paper. Carefully slide the coffee filter paper over the top of the cotton balls, ensuring that it covers the entire surface area.

You can secure it in place using a twist tie or rubber band, which will prevent the filter from slipping out while in use.

However, in the event that cotton balls are not available, do not worry. You can always improvise and use pieces of coffee filter paper instead.

Simply ball up the filter paper and put it on either end of the activated carbon, in between.This will help ensure that the water is properly filtered and free from any impurities or contaminants.

It’s worth noting that the coffee filter paper is a vital component of this water filter. It helps to capture any remaining debris or particles that may have passed through the cotton balls and activated carbon.

With this added layer of filtration, you can be sure that the water you are drinking is safe and free from harmful contaminants.

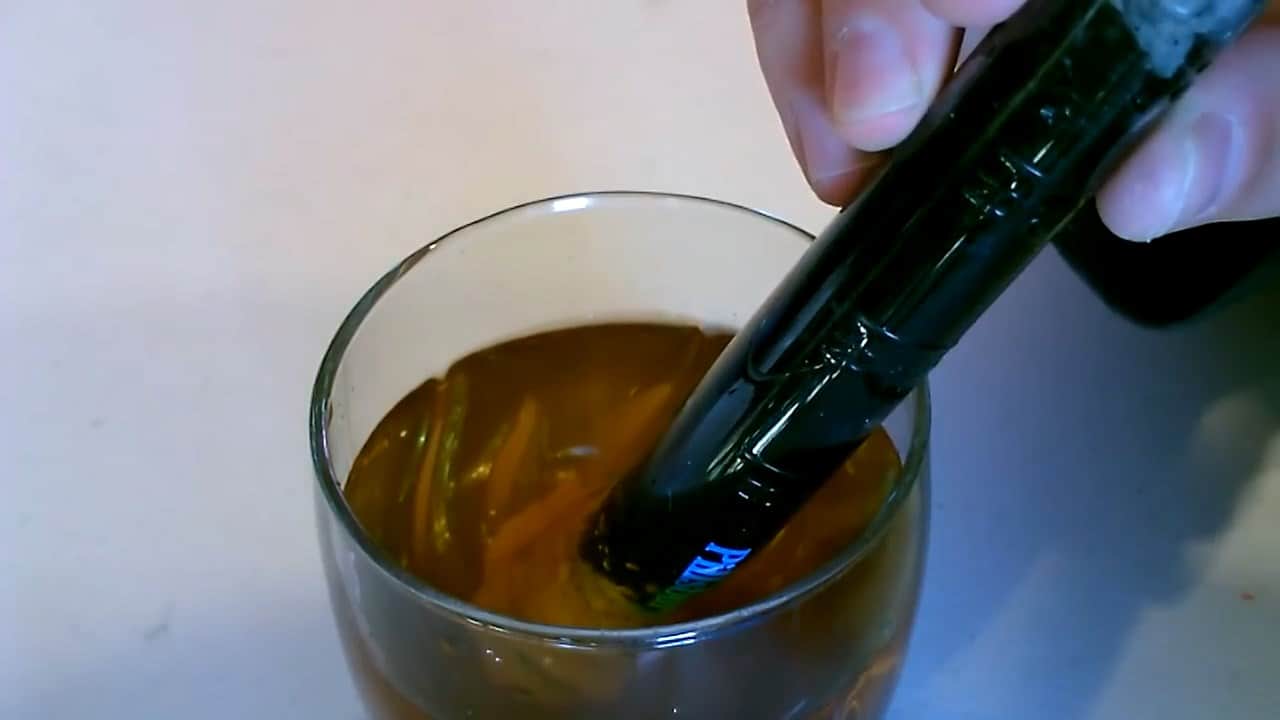

STEP 4 : MANUAL FILTERING

Another way to use this DIY water filter is to cut off the top of the poultry baster and attach it to the top of the straw.

This creates a small hand-held filter that can be used to manually filter water from any source, including streams, lakes or rivers.

Simply dip the straw into the water source and use suction to draw the water up through the filter. As the water passes through the activated carbon, cotton balls and coffee filter, contaminants will be removed and you’ll be left with clean, safe drinking water.

It’s important to note that this manual filtering method may require a bit more effort and time compared to using the filter as a straw. However, it provides greater flexibility.

As the filter is used, the materials inside will eventually become saturated and less effective at removing contaminants from the water.

When this occurs, the flow of water through the straw may slow down. To maintain optimal performance, it is important to periodically replace the cotton balls and coffee filter paper.

The cotton balls, in particular, will become dirty fairly quickly as they capture most of the dirt and debris in the water.

To replace the cotton balls, simply pull them out of the top of the straw and replace them with fresh ones. The coffee filter paper can be replaced by untying the twist tie or rubber band and sliding the old paper off, then sliding a new piece onto the top of the cotton balls and re-tying it securely.

Regular maintenance of the filter will ensure that it remains effective at removing contaminants and providing clean drinking water.

In conclusion, building a simple homemade pocket straw style water filter can be a lifesaver in emergency situations such as hiking, camping, or SHTF scenarios.

With easily accessible materials such as a turkey baster, cotton balls, coffee filters, and activated carbon, you can create a lightweight and powerful water filter.

Regular maintenance and replacement of the cotton balls and coffee filter paper can ensure that your filter lasts for years.

Remember that this filter is not a substitute for proper water treatment and it is always advisable to boil or chemically treat water from unknown sources before using this filter.

Image Credits : desertsun02