In this project, we will be exploring the construction of a homemade air heating and cooling system that uses water as its primary fuel.

The system is designed to pump cold or hot air into a room or space, with a high flow rate of 1500 CFM and a temperature range of 55F for cold air and almost 170F for hot air. The heat exchanger and an old car radiator fan are used in conjunction to create this system.

One of the major benefits of this air cooler/heater is that it is powered by a 100W solar panel, making it a sustainable and cost-effective option. This makes it an ideal solution for individuals who are looking to save money on energy bills and reduce their carbon footprint.

Furthermore, this system offers a significant advantage over traditional air conditioners, as it does not add any humidity to the air. This feature is especially important for people living in humid regions, where high humidity levels can lead to discomfort and respiratory issues.

STEP 1 : THE MATERIALS REQUIRED

To build your own water-fueled air cooler/heater, you will need the following materials:

- A standard bilge water pump or aquarium pump or 12V DC fan for solar power

- A 7-inch 12V 80W car radiator fan

- A 10 x 12 piece of plywood

- A couple of eleven inch 2x4s

- An 8 x 8 heat exchanger

- One inch PVC tubing

- A couple of hose barbs with coupler

- A container to hold the ice or hot water

- A 12V DC heating element (optional, for warming up the water)

These materials can be easily sourced from a hardware store or online retailer, and the total cost of the project should come out to around 60 to 70 dollars.

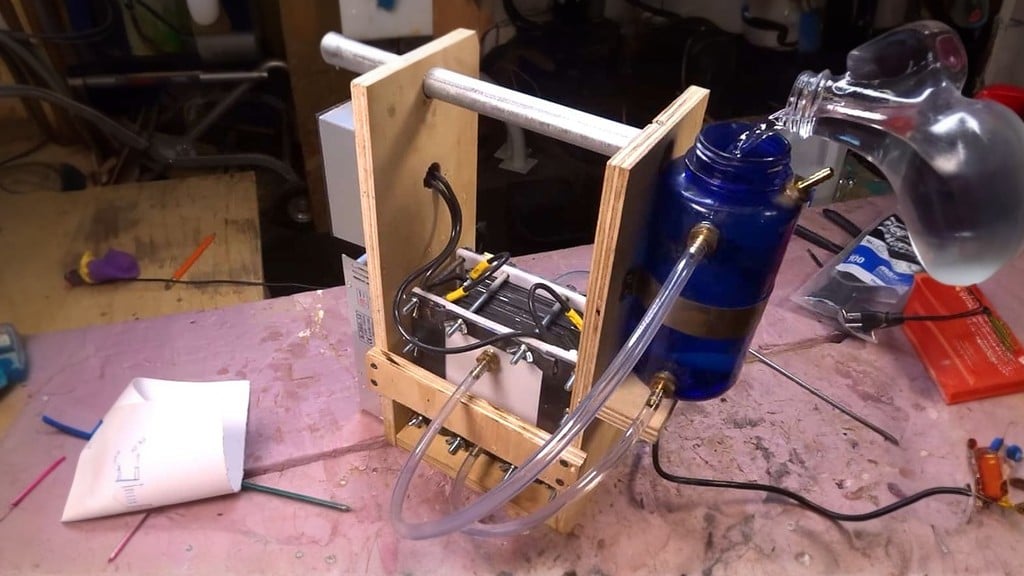

STEP 2 : BUILDING THE FRAME

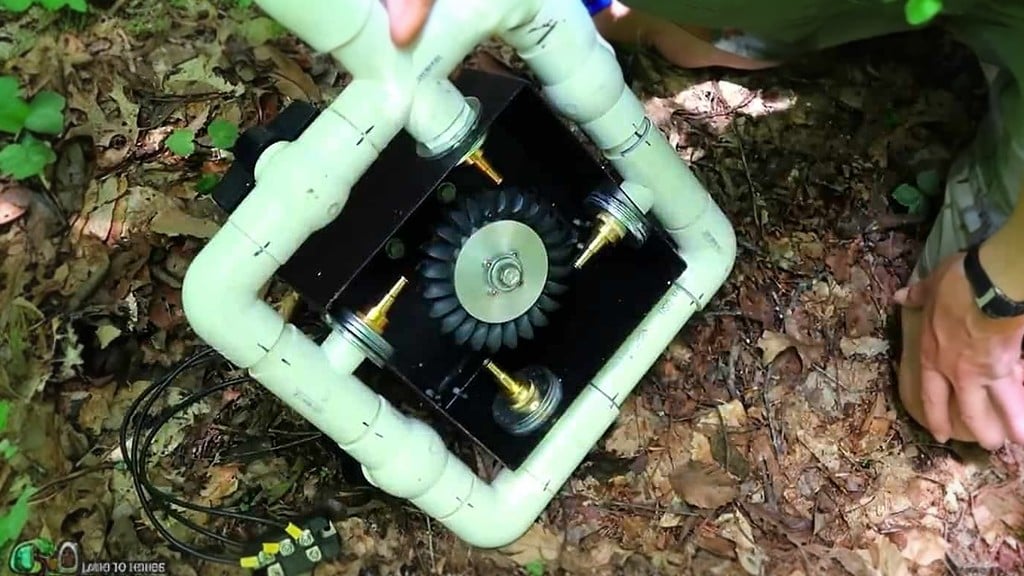

Once you have gathered all the necessary materials, the next step in building the water-fueled radiant air cooler/heater is to create a frame that will hold the heat exchanger and car radiator fan together.

To do this, you will need to take two 11 inch 2 x 4 pieces of wood and mount them parallel to each other onto the 10 x 12 inch piece of plywood.

Next, you’ll need to cut a hole in the plywood to fit the car radiator fan snugly. Once you’ve done that, attach the heat exchanger to the backside of the fan, positioning it between the two 11-inch 2 x 4s.

It’s worth noting that the heat exchanger should be rated for over 25,000 BTUs and cover approximately 1000 sq ft to effectively heat or cool the entire living space. This ensures that the system is powerful enough to provide sufficient air flow and temperature regulation.

STEP 3 : CONNECTING THE WATER SOURCE AND INSTALLING A SMALL WATER PUMP

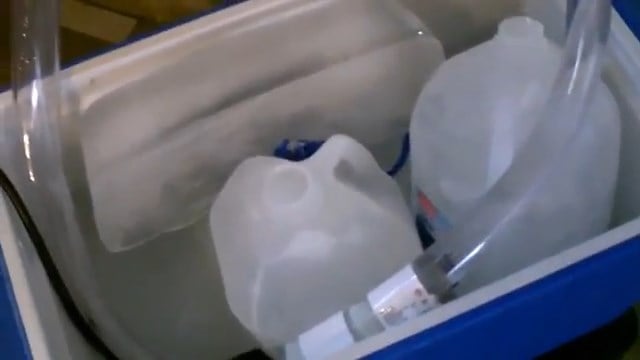

To use the homemade water-fueled radiant air heater/air cooler, a tub is needed to hold the ice-cold water or hot water.

The water pump, which can be a standard bilge water pump, an aquarium pump, or a 12V DC fan for solar, is then submerged into the water source and connected to the inlet tubing. This will pump the cold or hot water into the input of the heat exchanger.

Once the water is flowing through the heat exchanger, the car radiator fan is turned on using the 100W solar panel as the power source. This will cause the air to circulate through the heat exchanger and absorb the heat or cold from the water. The hot or cold air is then radiated into the room or space.

As the air is passing through the heat exchanger, it absorbs the heat or cold from the water, which in turn, cools or heats the air as needed. The heat exchanger used in this project is rated for over 25k BTUs and can cover an area of about 1000 sq ft. This means that it can heat or cool an entire living space.

Finally, the water returns back into the tub through the other tubing, completing the cycle. By using a tub of water as the source of heat or cold, this system has the advantage of not adding any humidity to the air.

The 100 W solar panel used in this project is connected to a speed controller that allows for adjustable airflow from the radiator fan.

This is particularly useful when you want to regulate the temperature in your room or space. The speed controller is a crucial component that helps to manage the fan’s speed, ensuring that it doesn’t draw too much power from the solar panel. It also makes it easier to maintain the desired temperature by adjusting the airflow.

The speed controller works by varying the voltage supplied to the fan, which in turn changes the speed of the fan. This means that when you need to cool down a room quickly, you can increase the fan’s speed to its maximum setting.

Conversely, when you need to maintain a comfortable temperature, you can decrease the speed of the fan to its lowest setting. With the speed controller in place, you can effectively balance the cooling or heating power of the system and ensure that it runs smoothly and efficiently.

To connect the 200gph water pump to the main inch pipe tubing, you will need a few pieces of hardware. First, use a half-inch barbed to inch threaded adapter to attach the half-inch pipe to the inch pipe main tubing.

Next, use an inch threaded to inch barbed adapter to connect the other end of the main tubing to the water pump. Finally, use a threaded PVC coupler to secure the connections and prevent any leaks. It is important to ensure a tight and secure fit to avoid any water leaks that could damage the system or surrounding area.

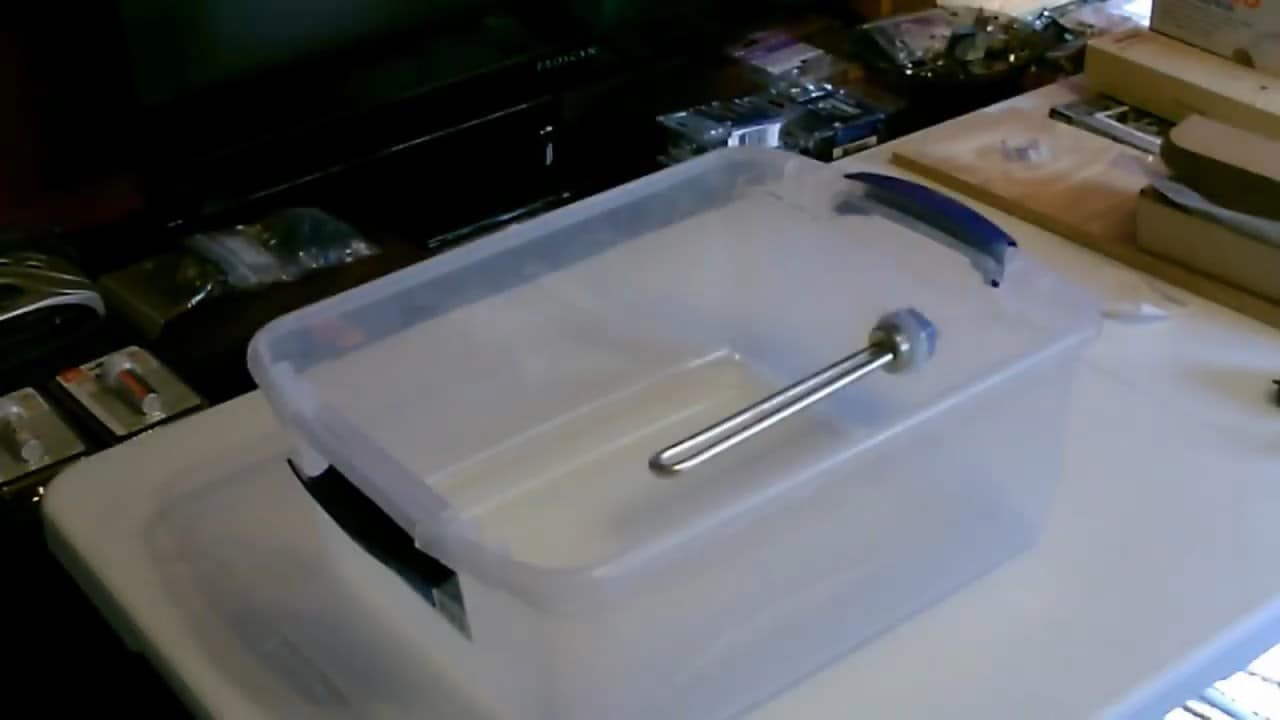

STEP 4 : ADDING THE HEATING ELEMENT

To generate hot water for the system, we incorporate a 150W DC water heating element at the bottom of the tub or barrel. The heating element is connected to a solar panel to harness the power needed to heat the water.

In case solar power is not available, an AC-powered immersion water heater can be used as an alternative.

The heating element is inserted into the tub, and the electrical connection is made through a water-resistant cable. Once the heating element is powered, it heats the water in the tub, which is then pumped through the heat exchanger, transferring the heat to the surrounding air before returning to the tub. This ensures that the system generates hot air to warm the living space

STEP 5 : ADDING THE SOLAR PANEL

The beauty of this homemade water fueled radiant air heater/air cooler is that it’s powered by a 100W solar panel, which makes it both environmentally friendly and cost-effective.

The solar panel is responsible for powering two critical components: the 80W car radiator fan and the 12V 350 GPH bilge pump.

The bilge pump is used to pump the water to the heat exchanger and back. It is essential for ensuring that the cold or hot water circulates throughout the system and that the hot or cold air radiates into the room or space.

The solar panel provides enough power to keep the bilge pump running continuously, guaranteeing that your room or space remains at a comfortable temperature.

Furthermore, the solar panel also powers the heating element if you plan to heat the water this way. To heat the water using this method, a 150W DC water heating element is connected at the base of the tub or barrel.

This heating element is powered by the solar panel, ensuring that you get to enjoy a warm and comfortable living space without incurring any extra costs.

Another way to heat the water is using a 50 ft copper tubing. The water is pumped through the copper tubing using a small pump and a 5W solar panel.

The solar panel provides enough power to keep the pump running continuously and heat the water. The hot water is then passed through to the heat exchanger, where it gets converted to hot air that is blown into your room or space.

In conclusion, building a homemade water-fueled radiant air heater/air cooler can be a cost-effective and environmentally friendly way to heat or cool your living space.

By using a heat exchanger and an old car radiator fan, this system can pump out cold air at 1500 CFM and heat output at almost 170 F, powered by a 100W solar panel.

With a few basic materials and some DIY skills, you can easily create a functional and efficient air heating and cooling system that can be customized to your needs. This project offers a great opportunity to learn about renewable energy

Image Credits : desertsun02