In this project, we demonstrate how to create a functional wind generator using a variety of materials that may be considered “junk” or scrap.

These materials include a ceiling fan, a microwave oven transformer, an office chair, an old TV tower, and other miscellaneous electrical parts.

To construct the wind generator, we repurpose the blades of an old ceiling fan and reinforce them with wood and fiberglass to increase their strength and durability.

We then attach these blades to a hub using a scrap piece of pipe as the shaft.

To further enhance the generator’s structure, we incorporate an office chair frame that can move freely and weld it to the pole/post of the turbine.

This frame is then welded to an old TV tower to create a sturdy and stable base for the generator.

STEP 1 : ASSEMBLING THE COMPONENTS

To create the wind generator, a scrap piece of pipe is used as a shaft that is attached to the hub of the turbine.

An office chair frame is then welded to the pole or post of the turbine in a way that allows it to move freely.

This office chair frame is further welded to an old TV tower, which serves as the main support structure for the wind generator.

The purpose of the office chair frame is to allow the wind generator to turn and face the wind direction, thus maximizing its efficiency.

STEP 1 : ADDING THE OVEN TRANSFORMER

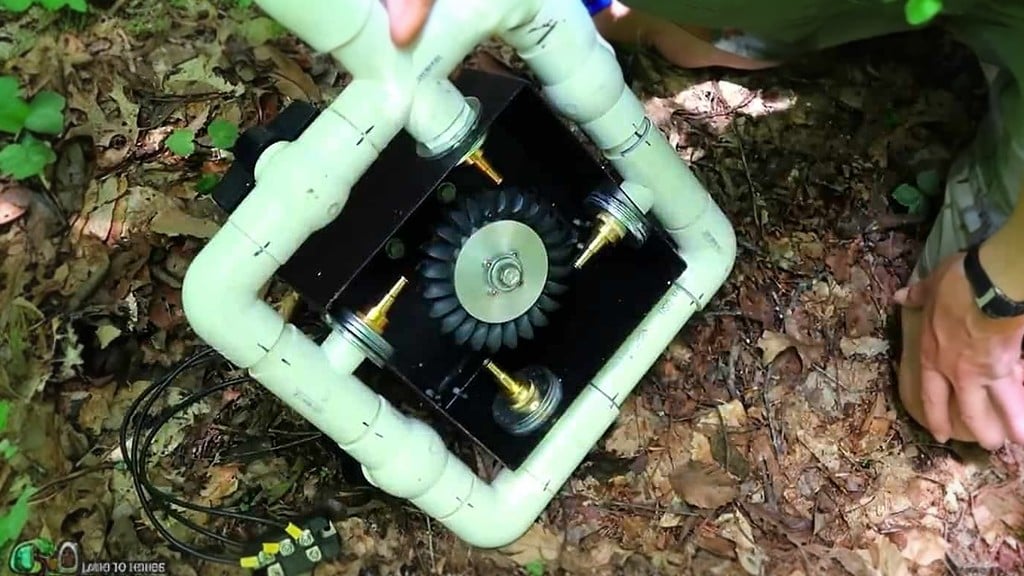

The next step in building the homemade wind generator involves attaching four magnets to the hub of the turbine.

These magnets are then aligned along their respective poles in north-south directions and glued to the bracket using a two-part epoxy.

.A frame from an old microwave oven transformer is then cut, exposing its core, which is subsequently welded onto the brackets.

As the magnets rotate over the transformer core, the process of electromagnetic induction takes place, generating an electric current.

This current can be used to charge a battery or to power lights and other electrical appliances. In order to generate more power, a multi-transformer setup can be used.

This would involve connecting multiple transformers together, resulting in a higher overall power output from the wind generator.

STEP 2 : CONVERTING AC TO DC

To make the most of the electrical current generated by the wind generator, we connect a rectifying diode to the output of the transformer.

This diode converts the current from AC to DC, making it more useful for powering appliances and charging batteries.

In addition, we use capacitors to smooth out the voltage and provide a steady direct current output.

To ensure that the battery is charged efficiently, we also incorporate a diode that prevents current from flowing back up to the generator from the battery.

This setup provides a simple and effective way to charge small batteries, making it a practical solution for off-grid power needs.

STEP 3 : ADDING THE MAGNETS

In order to improve the functionality of the wind generator, we attach a sheet metal piece onto the bracket of an old ceiling fan.

Next, we place four magnets at equal intervals on the sheet metal and align them in a north-south direction along their respective poles.

These magnets are then securely glued to the sheet metal bracket using a two-part epoxy.

The addition of the sheet metal bracket and the magnets ensures that the rotation of the turbine produces a higher amount of electrical current.

The sheet metal bracket enhances the stability of the setup and increases the resistance to the forces of nature.

The positioning of the magnets in a north-south direction aligns them with the earth’s magnetic field and maximizes the electrical current output.

STEP 4 : ADDING THE MOTOR

To increase the output of our wind generator, we incorporate an old 120V DC lawnmower motor. Due to the multiple poles in this motor, the magnets are situated very close to the armature, making it a more effective option than other types of motors.

This close proximity allows for stronger and more efficient electrical induction to occur, resulting in a higher wattage output.

However, it is important to note that this motor has brushes which will eventually wear out, requiring replacement after a few years of use.

Despite this drawback, this motor can produce approximately 100 watts of power, making it a valuable addition to our wind generator setup.

By repurposing an old lawnmower motor, we not only reduce waste but also utilize a resource that may have otherwise been discarded.

With this motor, we can generate more renewable energy and potentially power more appliances or charge larger batteries.

Overall, incorporating an old lawnmower motor into our wind generator setup provides a cost-effective and efficient way to increase the output of renewable energy, ultimately contributing to a more sustainable and environmentally friendly way of living.

Image Credits : kurtscottage | Youtube