This article is a detailed guide on how to build a simple off-grid refrigerator using a 5-gallon bucket and Peltier cooling technology.

STEP 1 : MATERIALS REQUIRED

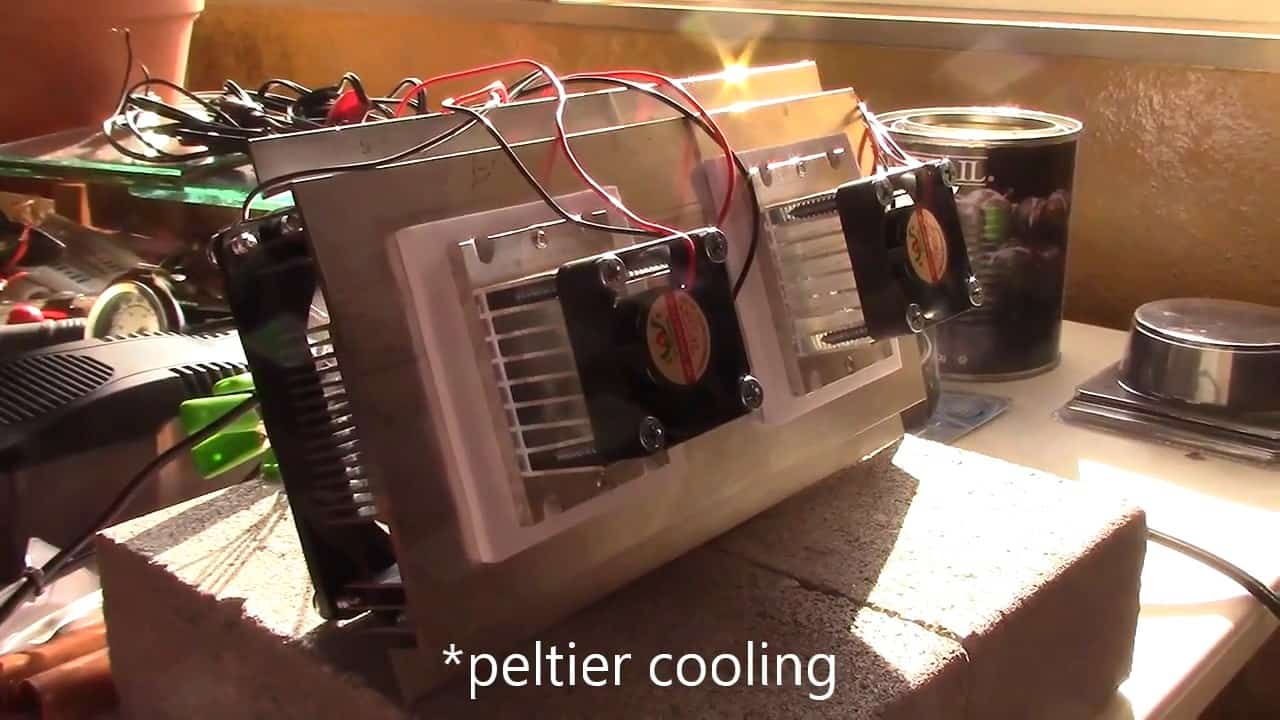

The primary component of the system is a 12V 12A Thermoelectric Peltier Refrigeration Cooling System unit, which can be easily sourced from online retailers such as Amazon.

Additionally, you will need a 5-gallon bucket that will serve as the main body of the refrigerator.

The bucket should be sturdy and durable enough to hold the weight of the cooling unit and other components. To insulate the bucket and increase the efficiency of the cooling system, a 4-gallon Styrofoam liner from a home improvement store such as Home Depot is necessary.

In addition to these main components, you will also require several smaller materials such as heat sinks, CPU fans, aluminum tape, and thermal paste, which will be used to optimize the performance of the Peltier cooling system.

STEP 2 : ADDING HEAT SINKS AND CPU FANS TO THE PELTIER CHIPS

The Peltier effect, upon which this off-grid refrigerator operates, is a phenomenon that describes the creation of a temperature differential when a DC current is applied across two different materials.

In the Peltier cooling system, this effect is achieved through the use of a Peltier unit, which is composed of two thin ceramic wafers with a series of n and p semiconductor materials sandwiched between them.

The ceramic wafers serve to provide both rigidity and the necessary electrical insulation for the module.

The n-type semiconductors within the Peltier unit have excess electrons, while the p-type semiconductors have a deficit of electrons.

These two types of semiconductors are combined to create a junction couple that creates the thermoelectric effect. When a DC current is applied to the circuit, the thermoelectric module can work as a cooler or a heater, depending on the direction of the current flow.

In this system, the Peltier cooling technology works by transferring heat from one side of the device to the opposite side, against the temperature gradient.

This transfer of heat creates a cooling effect on one side and a heating effect on the other. By using heat sinks and CPU fans, the heat generated on the hotter side of the Peltier unit can be radiated and lowered, while cooler air is moved into the bucket from the colder side.

This process allows the Peltier cooling system to effectively maintain a stable and cool temperature within the 5-gallon bucket, providing an off-grid refrigeration solution without the need for ice.

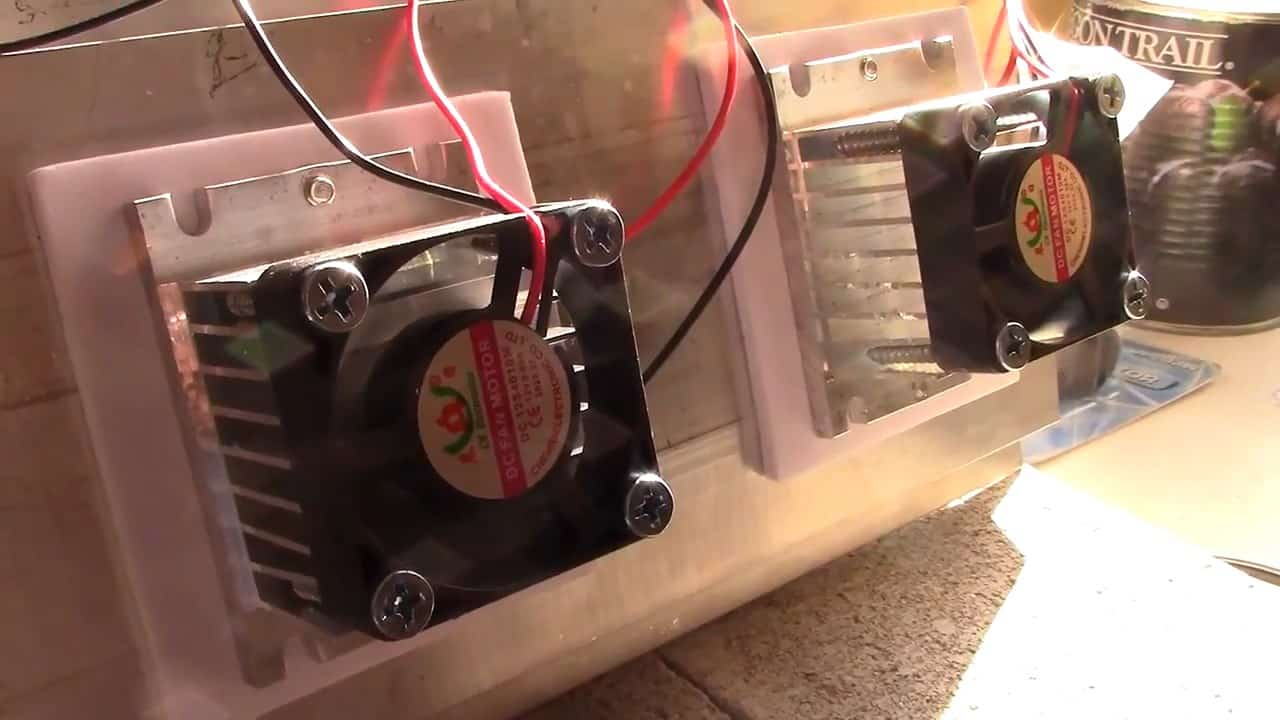

To ensure optimal performance of the Peltier cooling system, heat sinks and CPU fans are used on the Peltier chips to radiate and lower the heat generated on the hotter side and move the cooler air into the bucket from the cold side.

The heat sinks serve as a means of dissipating heat from the Peltier chips, while the CPU fans aid in air circulation, allowing for more efficient cooling.

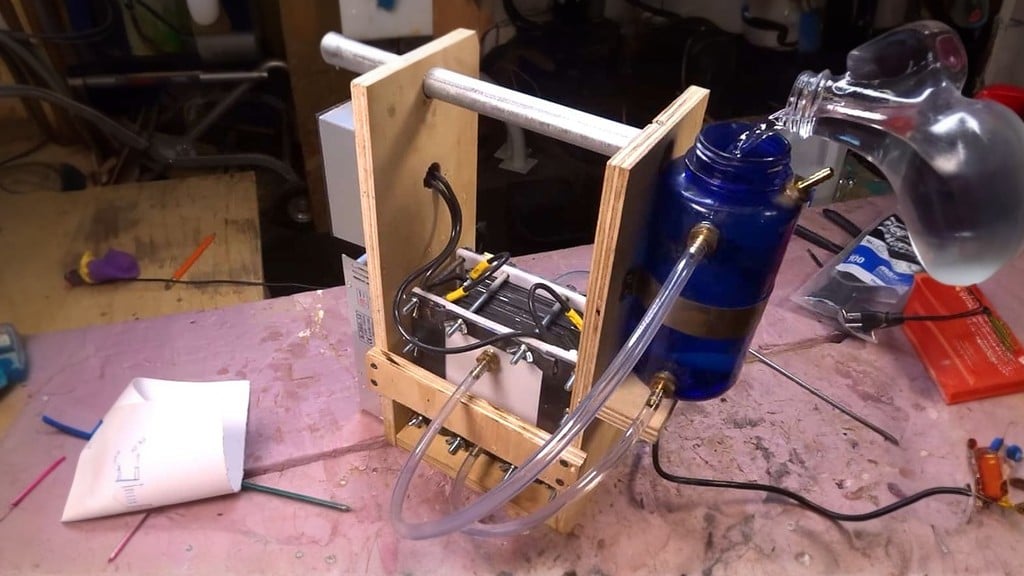

In this particular build, the Peltier setup is composed of two 12V 92mm fans that are attached to a large 200mm X 100mm aluminum heat sink on the hotter side of the Peltier unit.

This configuration allows for the efficient transfer of heat away from the Peltier unit, ensuring that the system does not overheat.

Additionally, two 12V 5.8A Peltier chips are glued under two 40mm heat sinks using thermal paste. These heat sinks are designed to effectively absorb and dissipate the heat generated by the Peltier chips.

Finally, 2 40mm fans are attached to the heat sink, which further aids in air circulation and ensures that the cooling system functions at maximum efficiency.

STEP 3 : INSERTING STYROFOAM LINER

To optimize the efficiency of the Peltier cooling system, a Styrofoam liner is inserted into the 5-gallon bucket. This liner acts as insulation, preventing heat from entering the bucket from the outside and maintaining a consistent temperature inside the bucket.

To ensure that the heat sinks are properly integrated into the liner, two small rectangular cuts are made on the lid of the liner.

These cuts allow the heat sinks to fit snugly into the liner, ensuring good airflow around the edges of the heat sinks.

This airflow helps to dissipate any excess heat generated by the Peltier cooling system and ensures that the system operates at maximum efficiency.

It is important to note that the cuts made in the Styrofoam liner must be precise and aligned with the heat sinks to ensure that they fit properly.

Any gaps or misalignments can reduce the efficiency of the Peltier cooling system and compromise its ability to maintain a cool temperature inside the 5-gallon bucket.

STEP 4 : MOUNTING THE PELTIER MODULE

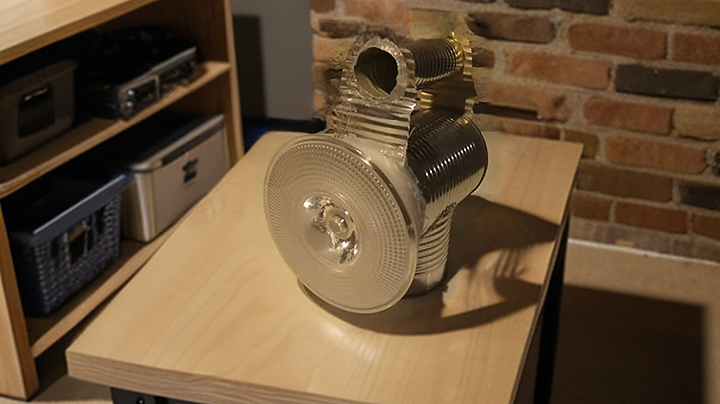

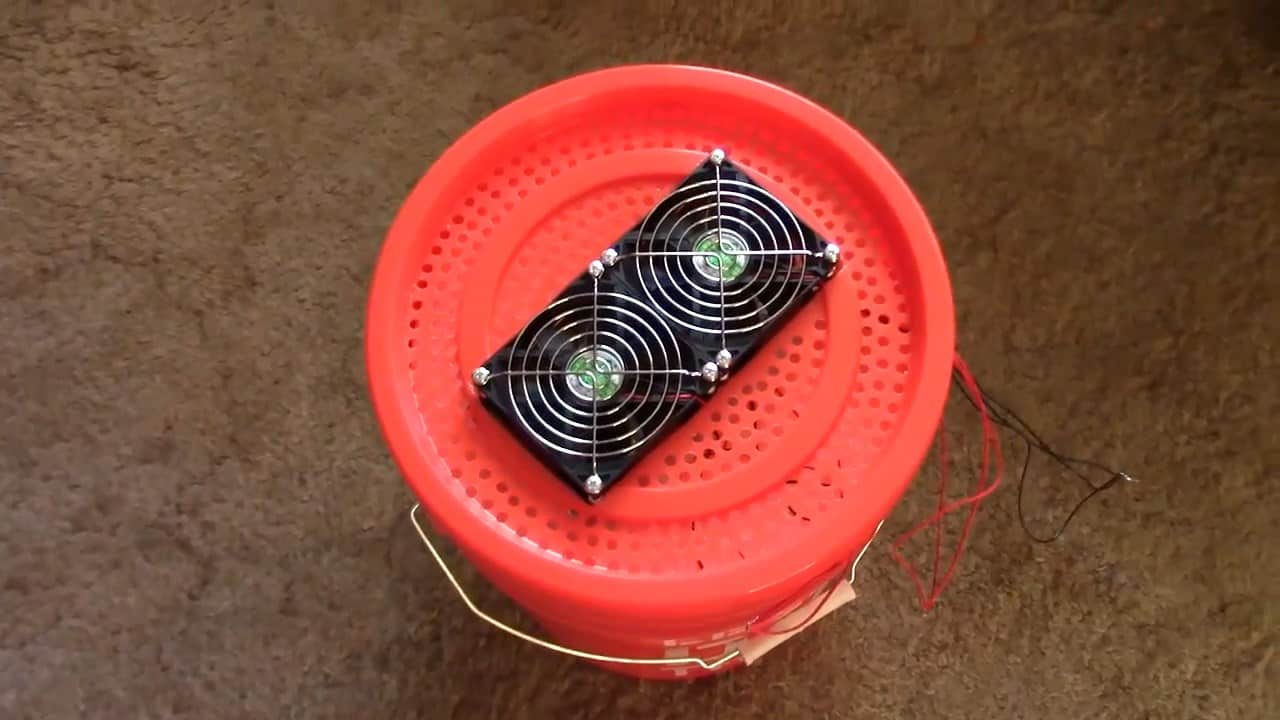

To properly mount the Peltier module in the 5-gallon bucket, a rectangular cut is made on the top lid of the bucket. This cut allows the Peltier module to fit snugly into the lid and ensures that it is securely mounted in place.

Additionally, small vent holes are drilled on the sides of the lid using a standard quarter-inch drill bit. These vent holes help to prevent hot air from becoming trapped between the bucket lid and the Styrofoam lid, which could compromise the efficiency of the cooling system.

By allowing air to flow freely through the vent holes, the Peltier cooling system is able to maintain a consistent and cool temperature inside the 5-gallon bucket.

To ensure that the wires from the Peltier units are properly routed and secured, a small notch is cut in the bucket using tin snips. This notch allows the wires to exit the bucket without getting pinched or damaged under the lid.

It is important to cut the notch in a location that provides sufficient clearance for the wires and does not interfere with the operation of the Peltier cooling system.

Properly routing the wires through the notch ensures that they are secure and do not become tangled or damaged during operation.

One of the benefits of this off-grid refrigerator is its versatility in terms of power sources. The unit can be hooked up to a variety of power sources, including 100-watt solar panels, a 12-volt deep cycle battery, a 12-volt transformer to the wall, or a car CIG lighter.

This flexibility allows the unit to be used in a variety of settings and situations, making it an ideal solution for off-grid living, camping, or emergency situations.

Furthermore, the efficiency of the Peltier cooling system allows the unit to rapidly cool the contents of the 5-gallon bucket. In fact, this unit can drop the temperature inside the bucket from 81 to 47 degrees Fahrenheit in a matter of minutes.

This rapid cooling capability ensures that food and beverages can be quickly chilled and kept fresh, even in remote or off-grid locations.